On 12 June 2013, the New York City Council passed an amendment to an existing law that effectively bans polystyrene food packaging from 1 July 2015. The legislation says that from this date, “…no food service establishment, mobile food commissary or store shall sell or provide single service articles that consist of expanded polystyrene.”

The styrene industry was quick to fight back, in fact the American Chemistry Council (ACC) was poised to respond to this outcome and released a statement the same day saying that replacement materials would be prohibitively costly and that recycling would be a better outcome than the new legislation, which the ACC claims, “…has the potential to cost New York City and state nearly $100 million per year and will do little to reduce solid waste.”

The ACC has created a website to put forward its position:

Mayor Bloomberg raised the red flag with his warning statements in his State of the City address in February this year:

“One product that is virtually impossible to recycle and never bio-degrades is Styrofoam. But it’s not just terrible for the environment. It’s terrible for taxpayers. Styrofoam increases the cost of recycling by as much as $20 per ton, because it has to be removed.”

As Doris has reported in an earlier blogpost there are some alternative, bio-based and bio-degradable polystyrene foam packaging products available but, at this point, there is little choice of commercially available materials, and even PLA, which can be used for some applications, while bio-degradable in theory, is not always compostable in municipal facilities.

Styrene use is coming more and more under scrutiny. Styrene is under pressure from the Department of Health and Human Services, which lists styrene in its report of 23 June 2011 as, “…reasonably anticipated to be a human carcinogen based on limited evidence of carcinogenicity from studies in humans, sufficient evidence of carcinogenicity from studies in experimental animals, and supporting data on mechanisms of carcinogenesis.”

This classification was challenged in the DC courts by the Styrene Research and Information Center Inc but the judge threw the challenge out summarily, saying, “…the plaintiff’s arbitrary and capricious challenge fails.”

In light of these successful challenges to the acceptance of styrene and growing concerns over its safety, the downstream industry is looking for alternatives.

Several companies have been developing styrene-free resins in areas such as unsaturated polyester resins (UPR), where styrene is usually about 34% of the composite material.

Apart from health concerns, styrene use in UPR is falling because OEMs and consumers do not want styrene odour in automobiles and other applications–This means use in vehicle interiors is excluded.

Some pipe applications (about 18% of total UPR) avoid styrene- based formulations. (Eg. Drinking water pipes).

Workers and manufacturing employers want to keep styrene emissions in the manufacturing process at minimal levels for health reasons–The US Occupational Safety and Health Administration allows 100ppm (8hours weighted average) but the industry stipulates 50ppm and SIRC, the Styrene advocacy organisation, recommends 20ppm

In addition to the US classification, styrene is coming under scrutiny in Europe. In December 2012, the Committee for Risk Assessment (RAC) of the European Union upheld some parts of a Danish recommendation that classified styrene as a substance causing damage to the hearing organs through prolonged or repeated exposure via inhalation and as a substance suspected of damaging the unborn child.

These factors are increasing public awareness and concern over styrene toxicity/ exposure risks. The industry has been introducing styrene reduced or styrene free solutions.

There are already signs of changes in the definition of styrene in the US and Europe in 2011 and 2012 that mean all UPR producers recognize they need to expand their styrene-free/low-styrene offerings.

New low-styrene and styrene free developments:

Ashland reports that they have developed a 13% styrene reduced resin that has been successfully tested by customers in laminate and casting resins applications

DSM has developed styrene free resins without vinyl toluene or acrylates, which they say can cover about 75% of all UP resins applications. The cost is higher than for traditional alternate diluents. The DSM Atlac ® Brand UP resins are smell friendly, avoiding one of the major objections to styrene resins.

CCP has introduced its ENCORE PRIME resins, which are styrene-free, low odour, and offer the same mechanical properties as standard unsaturated polyester resins.

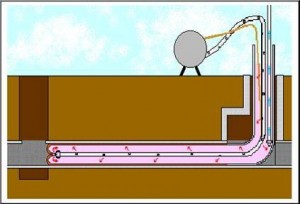

The range is mainly targeted at high temperature moulding and more specifically SMC and Cured In Place Pipe (CIPP) applications. Styrene free resins for pipe re-lining are appropriate for pipes near residential areas to avoid smell.

AOC is also offering styrene-free UP resins for many applications, notably CIPP applications where several styrene-free alternatives are available.

We can see with the ban on EPS in NYC and from the increasing concerns in Europe and the US over styrene regulation that the industry needs to prepare to reduce or in some cases remove styrene from various downstream applications. At the moment, cost remains prohibitive for many applications, but the writing is on the wall and in many downstream areas, including UPR, we are likely to see less and less styrene tolerance. Styrene will probably still have its place for many years to come, but downstream and intermediates users need to be prepared for the possibility that they may come under pressure from consumers, end-users or legislators to remove or reduce styrene content in their products.

For more information on UP Resins and the trends toward low-styrene and styrene-free materials, see the Tecnon OrbiChem presentation, Styrene’s Changing Role as a Feedstock for UPR from APIC 2013 in Taiwan here, on the Tecnon OrbiChem website:

Philippa Davies

Business Manager

Maleic Anhydride, Acrylates, Urethanes and UPR

Tecnon OrbiChem

Email: philippa.davies@orbichem.com

www.orbichem.com

FOLLOW ME ON THESE SPACE

That is really a good news in packaging industry. Thank you for the important information.

Posted by Sandeep Goyal | June 27, 2013, 11:56 am