Aside from Reverdia, several other biobased chemicals production milestones were announced this month such as from Solazyme and Amyris. Novamont did not actually put out an announcement (not in English anyway) but there had been several Italian news reports about the company’s bio-based 1,4 butanediol (BDO) activities worth mentioning — thank you Google Translate!

First stop is Solazyme’s announcement on December 13 where the company said it has successfully completed multiple initial fermentations at ADM’s Clinton, Iowa, facility. The fermentations were conducted in 500,000-liter vessels, 4x the scale of the vessels in Solazyme’s Peoria facility.

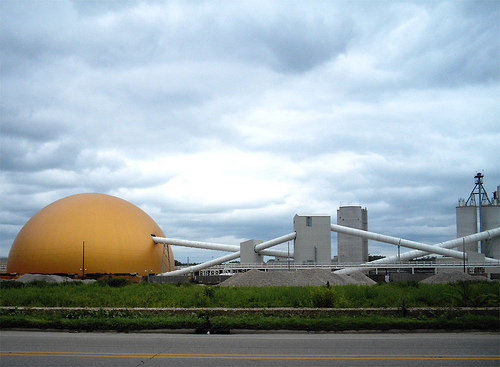

|

| ADM Clinton, Iowa, plant |

Solazyme is targeting 20,000 tonnes/year production of its algae-based tailored oils using corn dextrose (for feeding the algae) at the ADM facility starting early 2014, and expects to expand to 100,000 tonnes/year in subsequent years. Solazyme is currently constructing a 100,000 tonne/year facility in Moema, Brazil, under the Solazyme-Bunge joint venture, which is expected to begin operation in Q4 2013.

The key question here, as posed by analyst Lawrence Alexander of Jefferies & Company in a recent equity report, is whether the expertise used at Clinton can be extrapolated to the Moema site.

Amyris, meanwhile, announced on December 27 that it has successfully begun producing its plant-based farnesene (Biofene) at the company’s Paraiso fermentation facility in Sao Paulo, Brazil (under a joint venture with Paraiso Bioenergia and Grupo Sao Martinho). By how much, the company did not say but listening to Amyris’ earnings conference call held in November, the company mentioned the Paraiso plant is targeted to produce 50m liters/year of farnesene once it is commercially up and running.

|

| Amyris Paraiso facility in Brazil |

Amyris said it expects to step up to that level over a three-year period. In previous press statements, the facility is reportedly designed to process juice from up to 1m tons of sugarcane annually. The blog believes the Paraiso facility has about 6 fermenters and Amyris will open up two fermenters during the commercial start-up next year. Each fermenter is about 200,000 liters.

During the earnings call, management also noted that initial commercial production at the Paraiso facility is expected to start in early 2013 to meet anticipated demand not only for the company’s existing products such as farnesene-based squalene and diesel in niche markets but also to provide farnesene for emollient applications as well as certain polymers and lubricant applications.

By the way, other milestones that the company noted during their earnings call are the development of improved metabolic pathway to produce farnesene in yeast; development of farnesene strains capable of utilizing cellulosic sugars with similar yield as conventional sugars; and delivery of test samples of their farnesene-based fragrance oil to its partner Firmenich.

Another interesting update from the earnings call is that Amyris’ liquid farnesene rubber (in collaboration with European tire company Michelin) is said to have now advanced to the point where it is now ready to be used to start making a tire.

Amyris also announced last week that it has completed a $42.5m private placement of its common stock. The company sold 14,177,849 shares of common stock to existing investors. The transaction included $37.25m in cash proceeds from an outstanding senior unsecured convertible promissory note.

Finally, let’s talk about Novamont.

On December 3, France Italy-based bioplastic firm Novamont said it has completed the acquisition of a business unit of Tecnogen, the biotechnology research business owned by Sigma Financial Tau SpA. The acquisition is part of Novamont’s strategy to build its biotechnology business called Mater Biotech in joint venture with Genomatica, starting with the production of bio-based 1,4 BDO.

Early this year, Novamont purchased an amino acid facility in Adria, Italy, owned by BioItalia (a business of Ajinomoto), with the intent of converting the facility into producing bio-based 1,4 BDO. The newly converted facility will have a production capacity of 20,000 tonnes/year and is expected to start production by the end of 2013.

Novamont is financing the plant conversion and will operate it. The company has committed to purchasing all of the bio-BDO output from the plant while Genomatica may purchase a portion at its discretion to support further market development. Novamont said it will consume the BDO for its own internal use to meet increasing demand for its biopolymer products that incorporate BDO as a key monomer.

Novamont currently produces a biodegradable polyester — specifically polybutylene adipate co-terephtalate (PBAT) — under the trademark Origo-Bi using vegetable oils for feedstock. PBAT is made by polycondensation between 1,4-butanediol and a mixture of adipic acid and terephtalic acid (TPA). I have no idea how vegetable oils is incorporated in this particular polymer but Origo-Bi is actually a combination of Novamont’s vegetable oil technology and Eastman’s Eastar-Bio PBAT technology, which Novamont acquired in 2004.

Novamont currently has a 70,000 tonnes/year capacity to produce Origo-Bi, as well as 120,000 tonnes/year capacity to produce its Mater-Bi starch technology polymers in Terni, Italy.

Novamont is also working on its Matrica joint venture with Italian energy company Eni to build a biorefinery at Eni’s Porto Torres site. The biorefinery aims to produce bio-based monomers, lubricants, additives for rubbers, fillers and plastics using non-food based vegetable oils and lignocellulosic feedstock.No specific timelines have yet been announced for the construction and start-up of the Porto Torres biorefinery. Around 7 plants that will use Novamont’s technologies are expected to be built at the site in three stages.

FOLLOW ME ON THESE SPACE

Good to see you back and blogging, Doris. Have a happy New Year!

– Neil

Posted by naburns | December 31, 2012, 6:30 amThanks Neil! I hope you had a good holiday break. Happy New Year!

Posted by Doris de Guzman | January 1, 2013, 9:29 pmHi, your text mentionned the Novamont as a French firm, whereas there are many evidence to be Italian.

Can you explain better this point?

Posted by carlo | September 17, 2014, 10:55 amYes, it’s an Italian company. Sorry about that. I deal with a lot of companies and sometimes do make mistakes.

Posted by Doris de Guzman | September 18, 2014, 1:54 pm