Novomer said it has received a $5m grant from the US Department of Energy (DoE) announced in March as part of the Clean Energy Manufacturing Initiative (CEMI). Novomer’s project is in partnership with one of the world’s largest producers of industrial gases, aims to sequester and convert waste carbon dioxide into commodity chemicals such as acrylic acid, butanediol, etc. There are only very few major industrial gas producers around — Airgas, Air Liquide, Air Products & Chemicals, Linde, BOC Gases, and Praxair. Did I miss any other company?

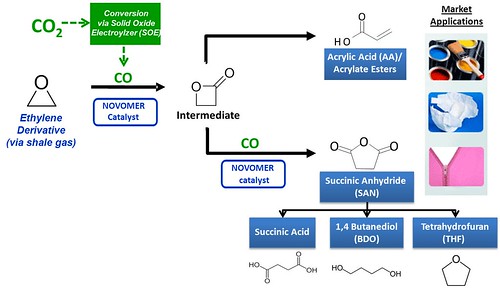

Novomer did not disclose who its industrial gas partner for the project. The partner’s role is to convert waste carbon dioxide (CO2) into carbon monoxide (CO) via solid oxide electrolyzing process. The electrolyzer operates like a fuel cell in reverse and can leverage the investments made-to-date by the government and private sector to more quickly commercialize the technology.

Novomer’s catalyst-based process will convert the CO and shale gas-based ethylene oxide into acrylic acid and other chemicals. Novomer is already planning to run a 2 ktpa pilot plant for producing acrylic acid by 2015, and full commercial-scale by 2017. Novomer said this could result in the first US acrylic acid plant built in over 10 years.

Novomer did not disclose who will be its partner for the CO2/EO-based acrylic acid plants but according to Mike Slowik, Director of Chemicals for Novomer, the company is in active negotiations with Fortune 500 chemical companies for collaboration with the acrylic acid production.

“Interests in our technology is very hot because of its cost-advantages and environmental advantages. Our ethylene oxide feedstock will come from shale gas while carbon monoxide is also a low-cost material. On top of that, our energy consumption is very low. We expect cost-savings of 20-40% against typical acrylic acid production.” – Slowik

With regards to energy consumption, Novomer’s catalysts can operate at around 30-50 degree Celsius compared to current acrylic acid processing that operates above 250 degree Celsius. None of the catalyst used are wasted in the process, according to Novomer. Energy productivity of their acrylic acid processing is expected to increase by 30-70%.

Novomer’s process can reportedly reduce carbon footprint by 40-110% depending on target chemicals. Novomer said it has not yet determined where it will source CO2 for the pilot plant but it can come from various sources e.g. H2 production or ethanol fermentation among others.

The blog also asked an update about Novomer’s polypropylene carbonate (PPC) polyols production in February at the Albemarle plant in Orangeburg, South Carolina. The PPC polyol, produced using carbon dioxide and propylene oxide, can replace conventional polyether, polyester and polycarbonate polyols.

Novomer said it has been able to do a 7-ton production run at the Albemarle facility. Customers are now testing the PPC polyols materials mostly for coatings and adhesives application. Novomer is looking to scale-up to larger quantities production, which is already in the planning phase.

FOLLOW ME ON THESE SPACE

This seems to be very interesting way to solution to pollution. Pinakin Patel, FCE

Posted by Pinakin Patel | October 4, 2013, 12:24 pmany chance you know the chemical structure of the catalyst they’re using?

Posted by Jay | November 24, 2016, 2:29 am