This is an interesting news for the blog that you can use tomato skins to make composite plastics.

This is an interesting news for the blog that you can use tomato skins to make composite plastics.

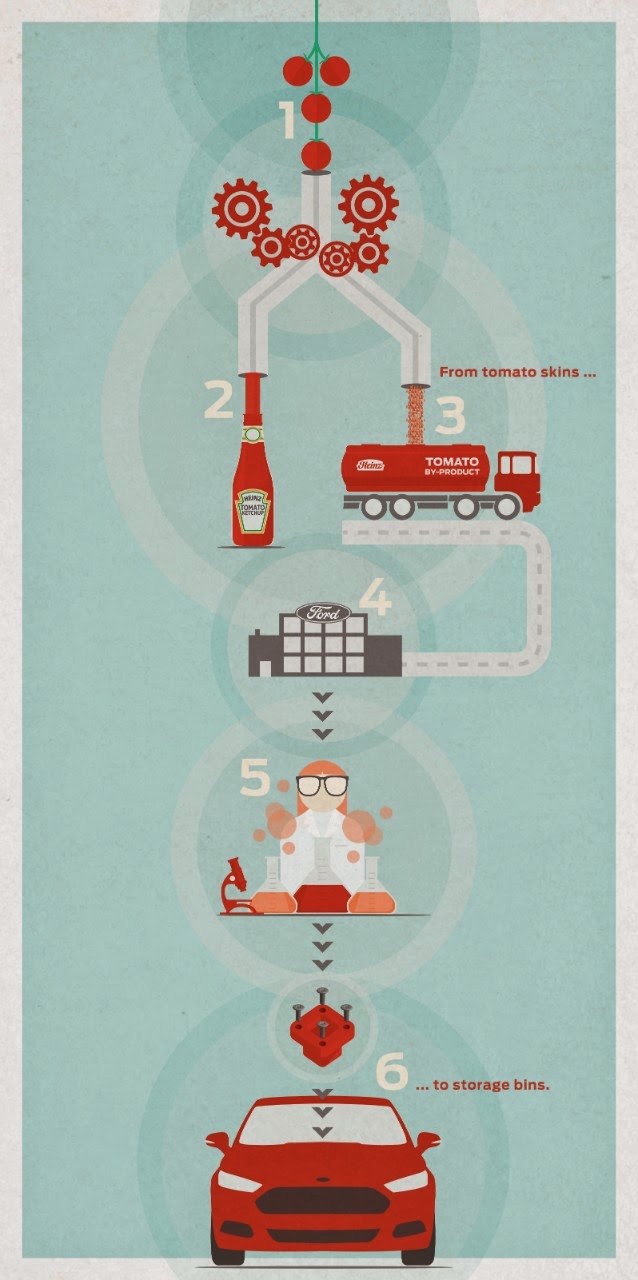

According to Ford and H.J. Heinz Company, researchers at the companies have been exploring the use of tomato fiber to develop a more sustainable bioplastic material for vehicle manufacturing. The companies have been using dried tomato skins to make composites for wiring brackets in a Ford vehicle or the storage bins used to hold coins and other small objects.

The researchers’ goal is to develop a strong, lightweight material that meets vehicle requirements while at the same time reducing the vehicle’s overall environmental impact. Heinz said it has been looking for innovative ways to recycle and repurpose peels, stems and seeds from more than 2 million tons/year of tomatoes the company use to manufacture its Heinz Ketchup.

The research is still in the very early stage phase, the companies said. Ford has been known to use other food-based waste materials such as rice hull in its electrical cowl brackets and cellulose fibers in console components. The company is also using coconut-based composite materials, recycled cotton material for carpeting and seat fabrics, and soy foam set cushions and head restraints.

FOLLOW ME ON THESE SPACE

Thank you for sharing such an interesting article! Hope to hear more information from you!

Posted by George Dionne | June 13, 2014, 10:54 am