My first school exam is coming up so I have to eased down my social media activities a bit (and here I thought being unemployed will give me more time to nap…).

According to this report from energy publisher SBI (which I saw on Specialchem.com), the market for bio-based epichlorohydrin (ECH) and biomethanol are the fastest growing segments in the bio-based chemicals industry because of the growing demand for biofuels.

What is the connection between ECH and biofuels, you ask?

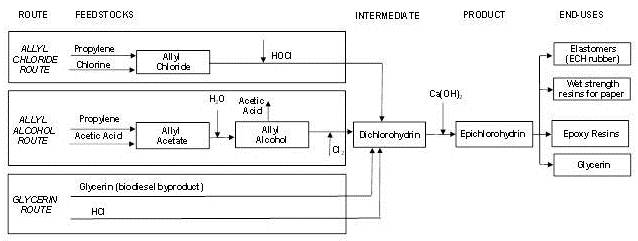

Traditionally, ECH (a chemical intermediate primarily used in the manufacture of epoxy resins) is produced via allyl chloride route using propylene and chlorine as initial feedstock or allyl alcohol route via direct oxidation of propylene in acetic acid as the initial processing step. The chart below from Chemsystems shows the routes towards ECH production. These petro-based routes produce synthetic glycerol as one of the byproducts.

In the past several years because of the deluge of crude natural glycerol as byproduct of biodiesel production, several ECH producers worldwide have looked into using glycerol as feedstock to produce ECH instead. Not only are there cheap, readily available crude cheap glycerol worldwide but it is also a bio-based material.

The glycerol-to-ECH process does not use solvents and also consumes hydrogen chloride as opposed to chlorine resulting in less chlorinated chemical waste.

According to SBI, when glycerin prices dropped to historical lows in 2009, producing bio-based ECH and biomethanol from glycerin became more economical spurring the market through 2011.

This year, Solvay’s Thailand-based affiliate Vinythai is building its second 100,000 tonne/year glycerol-to-ECH facility, this one to be located in Taixing, China, using Solvay’s Epicerol technology. The EUR 155m ($203m) investment is expected to start in the second half of 2014 and will use glycerin from biodiesel production.

Vinythai is already producing glycerin-based ECH at its first 100,000 tonnes/year unit in Map Ta Phut, Thailand, which started operating in February 2012. According to Solvay, for 1 tonne of ECH produced using the Epicerol technology, 1.1 tonnes of refined glycerin is used as feedstock and added with hydrogen chloride.

ICIS reported in 2010 that Dow Shanghai’s new 150,000 tonnes/year glycerin-to-ECH plant was supposedly expected to start this year as well as Samsung Korea’s 30,000 tonne/year glycerin-to-ECH plant.

So far, I have not seen or hear any updates on these projects. My theory is that these projects have been stalled probably because there have been a spate of petroleum-based ECH capacities that came onstream in China since last year. ECH operating rates in China now hover around 70% as demand for epoxy resins continue to soften because of weak global economy.

ICIS also reported companies such Yang Nong Jiang Su as already producing ECH from its 60,000 tonne/year facility in China using glycerine as feedstock. There was also news reports last year of Fujian Haobang Chemical running trials at its 5,000 tonne/year glycerin-to-ECH unit at Longyan in southern Fujian province.

Also in 2010, Italian CONSER S.p.A announced that Tangshan Risun Chemical Co. Ltd. signed a contract for purchasing CONSER’s ECH-EF (Epichlorohydrin via Glycerol) Technology for Tangshan Risun’s planned 100,000 tonnes/year facility in Tangshan, Hebei Province.

So far, I have not came across any other recent news on these Chinese companies coming onstream with glycerol-based ECH. By the way, Solvay has been very vigilant in protecting its Epicerol IP technology and some of these companies are probably already on their hit list (figuratively).

According to Solvay, the Chinese ECH market is expected to grow by 8%/year and accounts for 35% of total global ECH demand in 2016.

Meanwhile, Czech epoxy resin producer Spolchemie put on hold last year its planned 50,000 tonnes/year glycerin-to-ECH project in Malaysia because of financing issues. The company expanded its glycerin-based ECH production in Czech Republic from 24,000 tonnes/year to 30,000 tonnes/year through debottlenecking.

Going back to the SBI report, the market research firm said bio-based ECH will be selling the most volume of all bio-based chemicals in 2021 apart from glycerin and lactic acid. The report also cited as Malaysia being the largest exporter of refined glycerin; Argentina the largest exporter of crude glycerin although the EU still produces the largest share of glycerin.

In 2011, the biobased chemicals market was estimated at $3.6bn largely helped by stabilization of glycerin prices, according to SBI.

“Glycerin and lactic acid accounted for just over two-thirds of the bio-based chemical market by value in 2011. However, by 2021 this market share will shrink to 53% as the emerging markets for bio-based polyethylene (PE) and epichlorohydrin (ECH) achieve 10-fold growth through the decade.” – SBI

SBI expects the bio-based chemicals market to grow to $12.2 billion by 2021, accounting for 25.4 billion pounds of bio-based chemical production at the end of the decade. The overall growth of the market, however, greatly depends on the continued adoption of biodiesel to provide steady glycerin production and the market growth of new glycerin-based intermediate chemicals.

FOLLOW ME ON THESE SPACE

Excellent article!!!

Posted by Shao | January 12, 2013, 12:26 pm