I am about to fly to Caserta, Italy, to visit GF Biochemicals’ new levulinic acid plant, which started production in July. I will blog more about my trip later this week and will also tweet while at the site (hopefully my wifi is working). By the way, GF Biochemicals recently bagged the John Sime award given by the European Forum for Industrial Biotechnology and the Bioeconomy in Brussels for the most innovative new technology. The award was voted by the audience attending the recent EFIB conference.

In the meantime, here are recent updates on bio-butadiene developments.

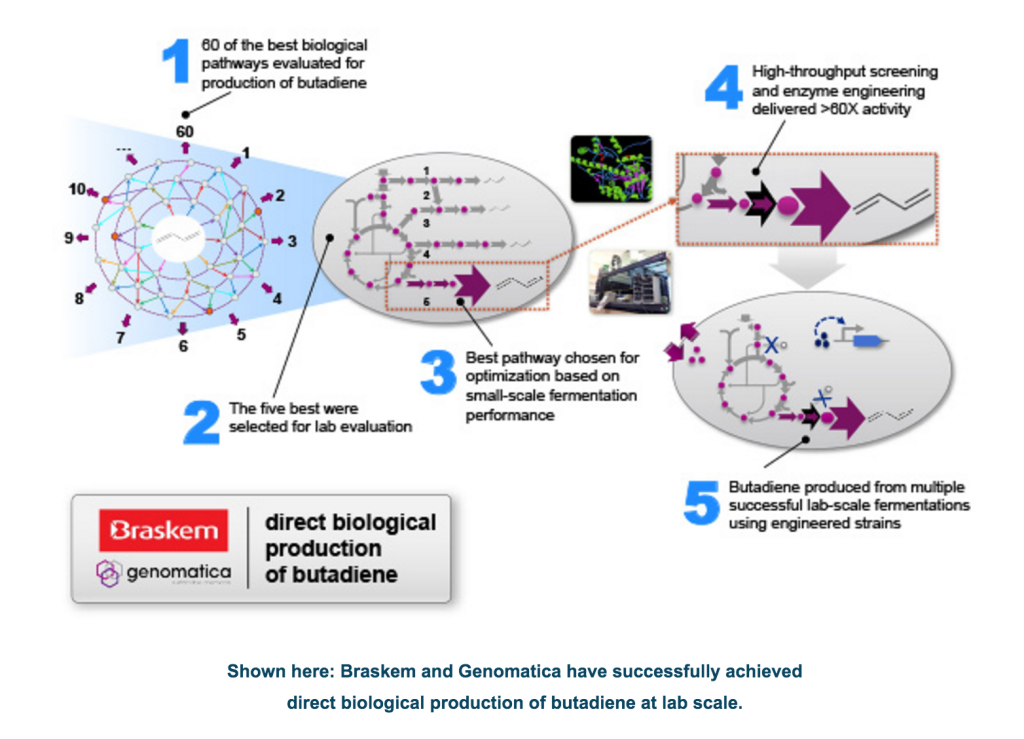

Genomatica and its partner, Braskem, announced late last month that they have successfully produced butadiene since June in a two-liter fermenters via a direct, continuous production. Genomatica was able to develop a microorganism using its computational tools that could theoretically make butadiene, and has identified 60 potential biological pathways. The five best selected pathways went through experimental validations, with Genomatica then multiplied the enzyme activity 60-fold on non-native substrates using its high throughput screening and enzyme engineering capabilities.

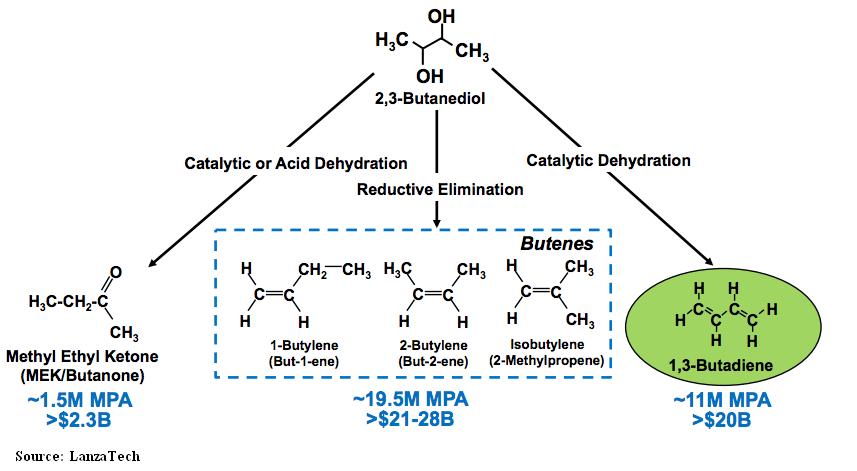

Invista and LanzaTech, meanwhile, recently announced that they have also successfully generate novel metabolic pathways to bio-butadiene and key precursors such as 1,3 BDO and 2,3 BDO, resulting in new direct and 2-step processes for butadiene using gas-fermentation technology.

Both companies are still in the early stages of developments especially for the direct-step process where bio-based butadiene can be directly produced without going through the 2,3 BDO fermentation route.

Two-step process to produce bio-butadiene

The blog previously mentioned several other companies developing bio-butadiene such as Global Bioenergies with Synthos; Michelin with Tereos/Axens/IFPEN; and Amyris and Kuraray working on farnesene-based polymers that can replaced petro-based butadiene and isoprene.

Butadiene is a raw material used in the production of rubber for tires as well as for electrical appliances, footwear, plastics, asphalt, building materials and latex. Genomatica estimated the demand for butadiene at over 20 billion pounds/year worldwide. Butadiene is traditionally produced using C4 stream petrochemical feedstock.

FOLLOW ME ON THESE SPACE

Discussion

Comments are closed.