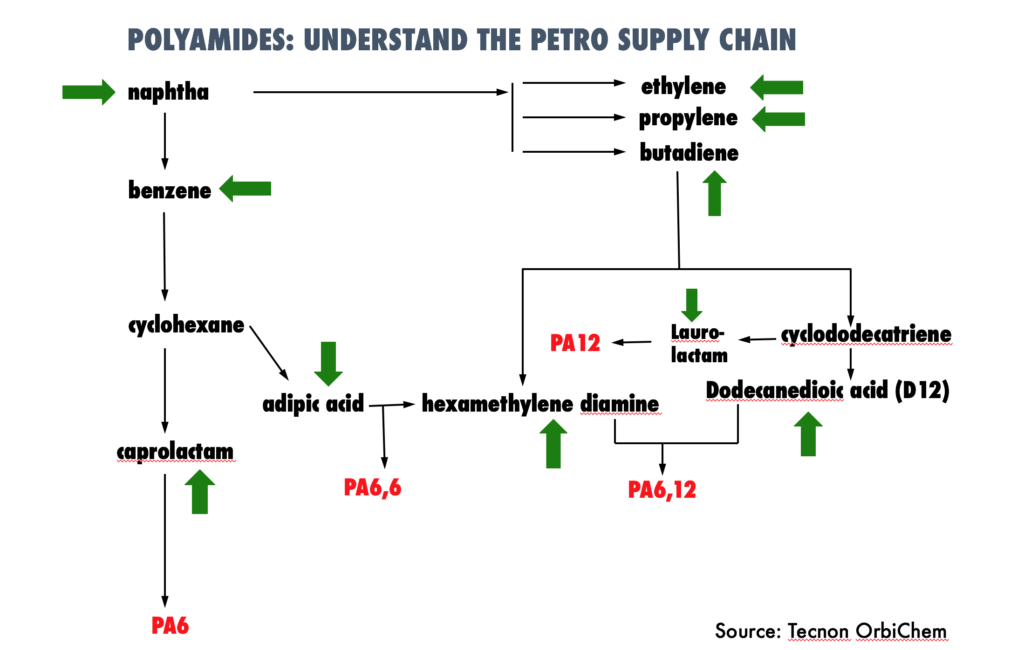

I’ve been always monitoring activities from the bio-polyamides sector as I consider the nylon industry a high-potential area for bio-based chemicals. Here’s a slide from a presentation I gave early this year featuring various building blocks and intermediates required to produce a certain polyamide. The green arrows indicate current R&D/commercial production for bio-based alternatives.

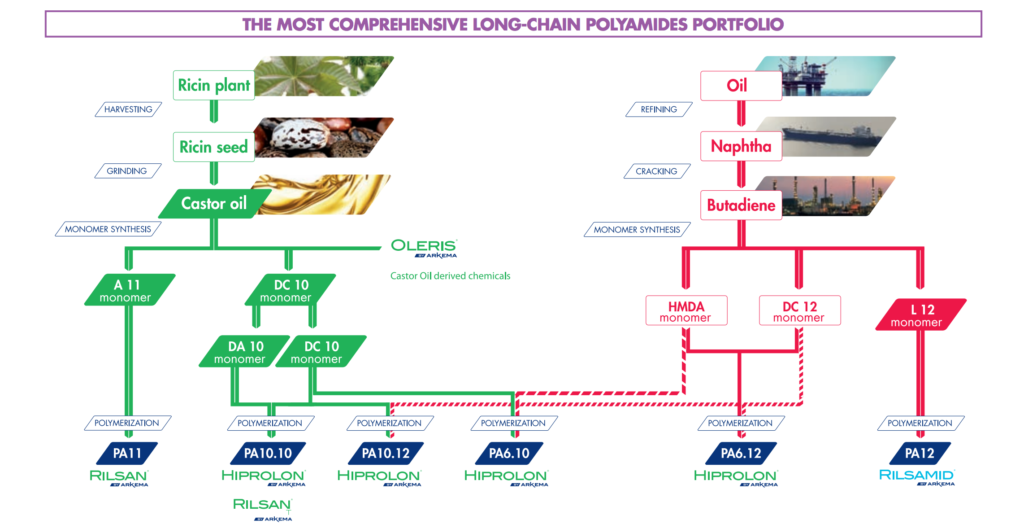

But of course, there’s the use of DA10 and DC10 monomers from sebacic acid (which comes from castor oil) that is being used in production of PA6,10; PA10,10 and PA10,12 as well as Arkema’s PA11 made from 100% bio-based 11-aminoundecanoic (A11) acid monomer (also sourced from castor oil).

Last month, Arkema announced that is expanding its specialty polyamides compounding capacities in Zhangjiagang site in Jiangsu Province, China, and will bring on stream in 2017 two production lines to manufacture PA11 in addition to PA10 already produced at the site. Arkema is also investing in its Birdsboro site in Pennsylvania to enable the manufacture of its new Pebax bio-sourced thermoplastic elastomer grades for the sports and electronics market. More information about this expansion and investments is reported at Tecnon OrbiChem’s Biomaterials newsletter September issue.

Aside from this news, there are also several annual sustainability reports that have been coming out, which I also monitor (among other things), and according to Arkema, it intends to make 15% of its turnover with renewable materials by 2016. The company cited its 5 biorefineries, the production of which, currently accounts for 13% of its sales.

- Marseille, France – A11 production and co-products glycerine, heptanaldehyde, heptanol, heptanoic acid and fatty esters which are being sold to the pharmaceuticals, paints, lubricant and fragrance amrkets.

- Hengshui, China (Casda Biomaterials) – sebacic acid, PA10

- Blooming Prairie in USA – epoxidized oils such as soybean oil and flaxseed oil, as well as terpenes from conifer resins for used as additives in polymer and lubricant formulations as well as the cosmetics industry

- Parentis plant in France – activated carbon from local pine wood

- Feuchy plant in France – fatty acids and surfactants

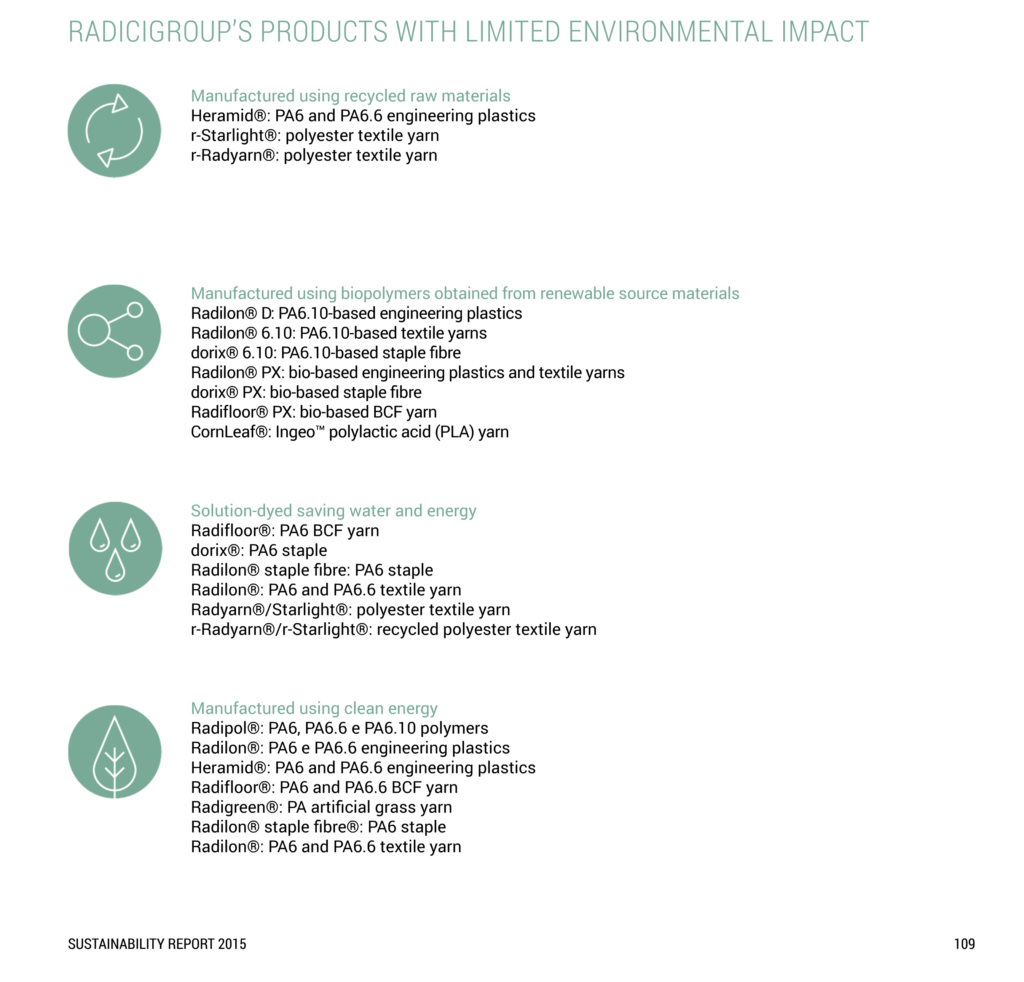

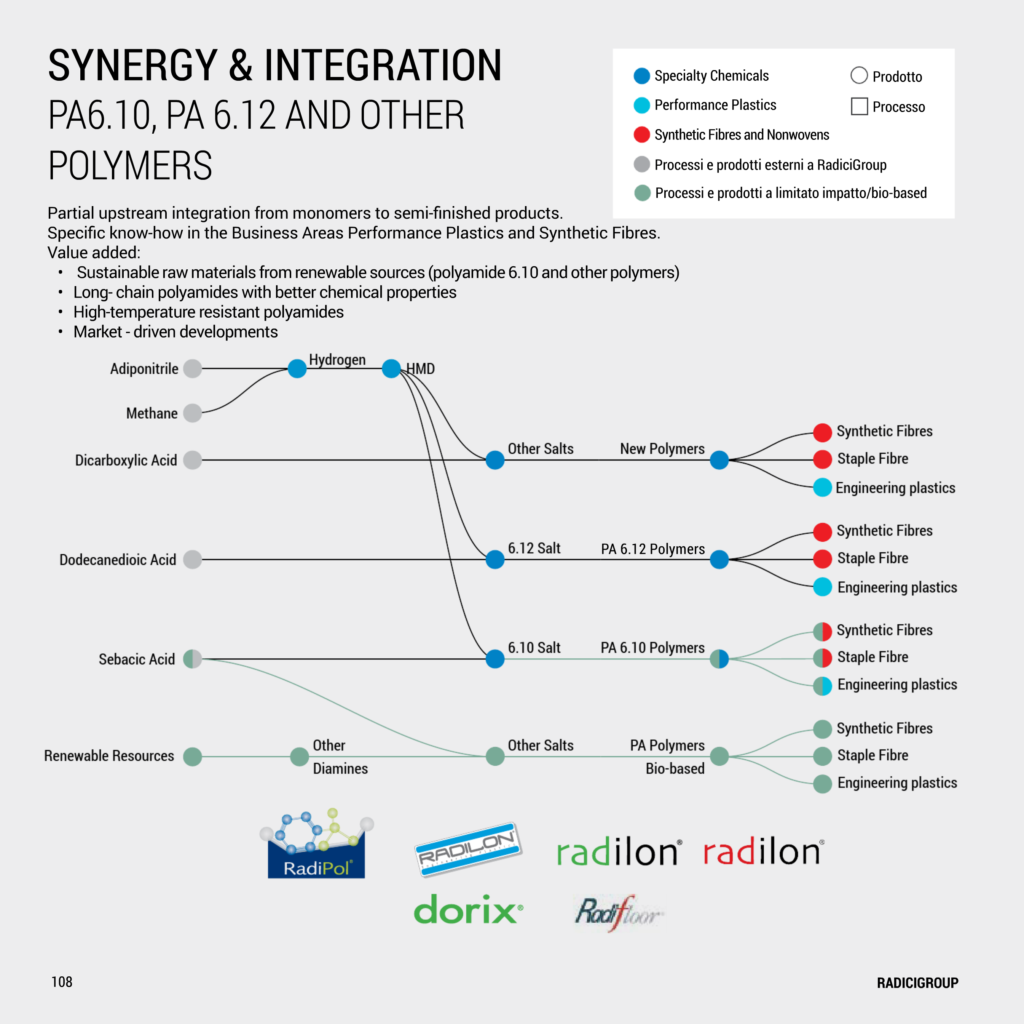

Back to polyamides, I also saw this interesting snippet of information from another bio-polyamide producer, Radici Group, based in Italy, on its annual sustainability report.

Hi. We at Arctic Biomaterilas Oy are pushing the limits by offering fully biodegradable composites to replace reinforced nylons. Would be interesting to hear your comments on this? Tomi kangas http://www.abmcomposites.com

Posted by Tomi kangas | November 9, 2016, 2:28 am