Updated 10/2/2013: Proterro emailed the blog for several corrections.

Sugar developer Proterro is in the process of commissioning a pilot plant in Florida, and has also already completed a preliminary design, layout and associated cost estimate for a demonstration-scale plant.

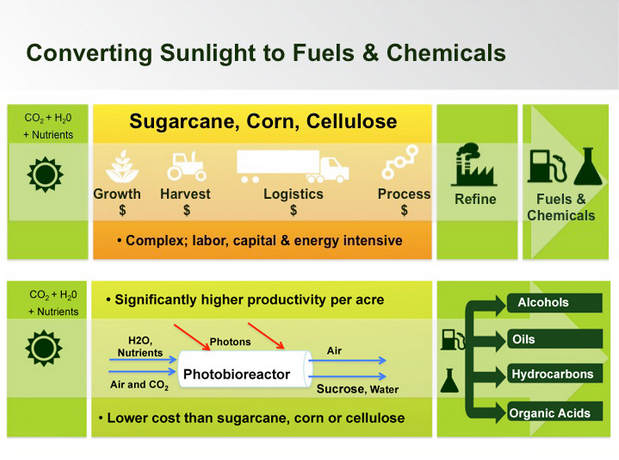

Proterro said it has developed a scalable biosynthetic process using carbon dioxide, sunlight and water to produce a fermentation-ready sucrose stream rather than a mixture of sugars allowing simple, low-cost downstream processes. The sucrose produced can be used as delivered, concentrated by water removal removal or purified to a grade depending on application.

Unlike typical algae cultivation, Proterro said its high sugar-producing cyanobacteria on a composite fabric substrate is enclosed in a modular photobioreactor, which optimizes the organisms’ access to light and surrounds them with carbon-dioxide feedstock. Water and nutrients are trickled into the photobioreactor creating a controlled cultivation environment.

The transgenic photosynthetic microorganisms are engineered to produce disaccharides. Photosynthetic microorganisms such as cyanobacteria can reportedly produce biomass at a much faster rate leading to much greater productivity. Direct production of disaccharides by microorganisms also avoids extensive energy-intensive pre-processing of using plant biomass to produce fermentable sugar.

This feedstock is definitely interesting as you only need sources of carbon dioxide to feed the microorganisms (as well as light and water of course). According to Proterro, the sugars they can produce can also be used as feedstock for yeast in fermentation production of chemicals or biofuel, or feedstock for algae (such as in the case of Solazyme’s processing).

The company aims to produce less than 10 cents/lb sucrose said it was able to lower the cost of its sugar production to around 5 cents/lb compared to 14c-15c/lb cellulosic sugars that are the goal of several developers. The company also reported no contamination affect on their sucrose productivity even when microbial contamination was deliberately introduced into their photobioreactors. This is because the cyanobacteria reportedly coexisted with other organisms and therefore sucrose productivity did not diminish.

Their process reportedly produces ready-to-ferment sucrose with yields currently 10 times 30 times more sucrose per acre than sugarcane.

Discussion

Comments are closed.