I have been learning more about pre-treatment processing for biomass as I don’t really cover much about this area. My interview with MBI (Michigan Biotechnology Institute) made me aware of the problems concerning the use of cellulosic feedstock for biofuel and bio-based chemicals application as the pretreatment process is a costly undertaking for companies to be able to use biomass for feedstock.

MBI is a multidisciplinary not-for-profit biotechnology de-risking center wholly owned by Michigan State University Foundation. The organization had impressive line-up of collaborators and clients such as DuPont, NatureWorks, Genomatica, Novozymes, Amyris, Verdezyne, Metabolix, Deinove, CBiRC, BioIndustrial Innovation Canada, etc.

MBI said it has been issued patent 9,102,964 for its innovative biomass pretreatment technology called AFEX, (Ammonia Fiber Expansion), which uses hot, gaseous ammonia to efficiently convert recalcitrant plant materials to a digestible form. The technology was conceived at MBI in 2010, and it reportedly enables a low-cost production of pretreated biomass while cost-effectively recycling and reusing the catalyst used during the process.

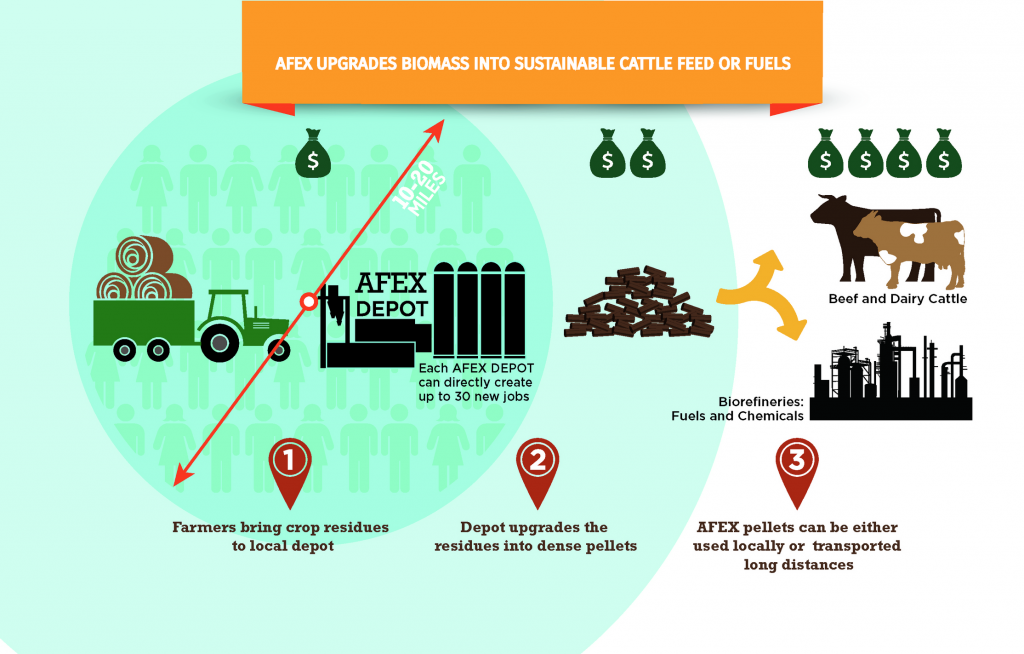

The AFEX technology has been scaled to the current 1 ton/day AFEX pilot plant at MBI’s Lansing, Michigan, facility. MBI said it has produced over 500 batches (15 tons) of AFEX pretreated biomass. The AFEX technology can readily address the logistical challenges inherent in transporting bulky and unwieldy biomass across long distances because the biomass is converted into dense, shippable, solid grain-like pellets, which can then be efficiently stored and shipped over long distances. The problem with current refineries that uses cellulosic feedstock is that they have to be near the biomass source to reduce logistics and storage costs.

According to MBI, implementing AFEX in a rural depot where biomass is locally sourced enables lower biomass transportation and logistics costs, and ultimately lower cellulosic sugar costs. It can kick-start the use of cellulosic sugars especially in chemical applications aside from biofuels with the use of low-density energy crops and agricultural residues. For every ton of corn, wheat and rice harvested today, an equal amount of biomass is left behind on the fields. Nearly 2 billion tons of biomass are produced each year around the world, according to MBI, and locked within it are huge stores of sugars.

In a separate news, MBI has also been collaborating with California-based Bolt Threads for the scale-up of its bio-based Engineered Silk. Bolt Threads claims to be the first company to produce Engineered Silk fibers made from proteins found in nature with the ability to scale commercially. The fibers can be programmed to be as soft, durable and malleable as needed. By accessing MBI’s expertise in process control and scale-up, Bolt Threads was able to develop a more robust and scalable production process capable of supplying large quantities of the engineered silk.

Bolt Threads is planning to have products in the market by 2016.

FOLLOW ME ON THESE SPACE

Discussion

Comments are closed.