There has been a significant increase in companies looking to convert methane-rich feedstock especially coming from natural gas, flare gas or even biogas (although this one is particularly expensive to do) into biofuels and chemicals. Some uses synthetic biology and others use thermochemical conversion such as gasification.

Examples include Calysta Energy, Intrexon, Enerkem, Siluria, Maverick Synfuels, etc.

Maverick Synfuels recently announced that it has partnered with Petrostar Petroleum Corporation, a Canadian-based oil and gas exploration company, and formed Maverick Northstar, Inc., a joint venture to facilitate the deployment and operation of gas-to-liquids (GTL) technology in the Canadian Provinces of Alberta, British Columbia and Saskatchewan.

Much of the methane in Western Canada is found in remote oil and gas fields where traditional distribution is not economically viable due to infrastructure choke points and discounted gas rates. Maverick said its modular production platform offers the first small-scale solution that can be co-located at the source of the methane. The platform converts methane and higher hydrocarbons into methanol that can be used on-site or transported to larger facilities nearby for conversion into higher value products such as ultra-clean synthetic fuels and chemicals.

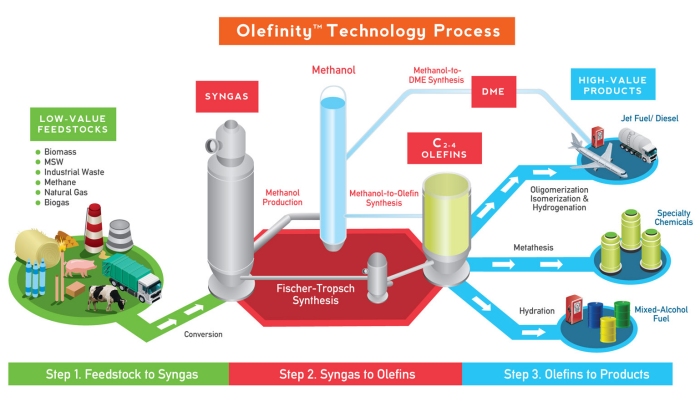

Converting methane gas to methanol liquid is one component of Maverick’s “spoke and hub” distributed production strategy that builds on Maverick’s patented Olefinity™ technology. Methanol produced at small-scale GTL plants (“spokes”) located at the waste gas source is easily transportable to larger “hub” facilities, where it can be converted to higher value products such as clean transportation fuels including dimethyl ether, diesel and jet fuel, or specialty chemicals like propylene using Maverick’s olefins based processes.

This approach significantly reduces capital requirements for converting low-value feedstocks such as waste methane into higher value products, according to the company.

Maverick has contracted with Plant Process Equipment (League City, Texas) to manufacture and sell small-scale gas-to-liquids plants (GTL). These modular plants are mounted on skids and can be quickly transported and installed remotely, even in difficult-to-access terrain. The plants can produce up to 10,000 gallons a day of methanol from methane-rich waste gas, or natural gas sources.

By the way, Calysta recently announced that it has achieved 8-fold improved performance in a high mass transfer bioreactor over traditional technologies in its quest to develop an efficient methane-to-liquids fermentation process. The improved performance was achieved in the research phase of a program funded in part by the department of Energy’s ARPA-E program under the REMOTE (Reducing Emissions Using Methanorophic Organisms for Transportation Energy) program.

FOLLOW ME ON THESE SPACE

Discussion

Comments are closed.