I am still working on that promised surfactant article I tweeted on Monday in preparation for next week’s World Surfactants Conference hosted by ICIS and Neil Burns LLC, of which I will be attending and will be tweeting as well (#Surfactants via @DGreenblogger). In the meantime, I am posting this press release from LanzaTech last week regarding its commercial ethanol facility investment in China.

Taiwan’s largest integrated steel maker, China Steel Corporation (CSC), has announced formal Board approval of a TWD 1,400 million ($46M USD) capital investment in a LanzaTech commercial ethanol facility. This follows the successful demonstration of LanzaTech’s White Biotech (WBT) Demonstration Plant in Kaohsiung using steel mill off gases from China Steel as raw material for ethanol production.

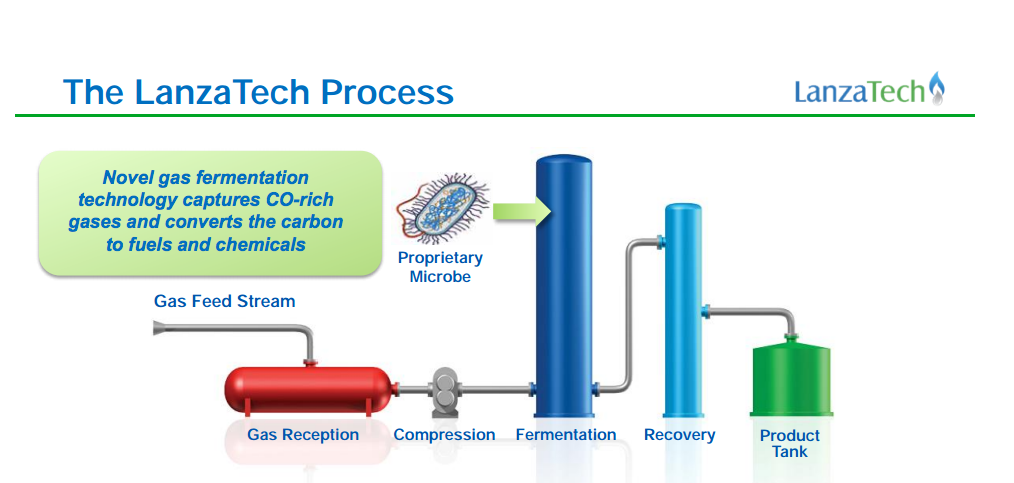

LanzaTech’s gas fermentation process uses proprietary microbes to capture and reuse carbon rich waste gases such as from steel manufacturing to make fuels and chemicals that displace those made from fossil resources.

In November 2012, China Steel Corporation (CSC) and LCY Chemical Corporation formed a joint venture, White Biotech (WBT), as part of a Green Energy Alliance with LanzaTech. The resulting demonstration plant met or exceeded all ethanol production milestones and the CSC Board have formally approved the capital to move to commercial scale. A 50,000 MT (17M Gallons) per annum facility is planned for construction in Q4 2015, with the intention to scale up to a 100,000 MT (34M Gallon) per annum commercial unit thereafter. Initial product focus will be industrial ethanol and gasoline additives, with plans for increased product diversity utilizing LanzaTech’s unique microbial capability.

I wonder if the ethanol produced will be cheap enough to use as a feedstock to make ethylene and derivatives. Just think about ethylene glycol (to make PET or polyester), polyethylene and ethylene oxide (to make surfactants) using waste gas? It’s a very good marketing tool provided the economics of it are sound enough to compete with coal-based/naphtha-based/shale-based ethylene.

Discussion

Comments are closed.