I guess Amyris will have some serious competition for its sugar-based squalene. Calyxt, a synthetic biology company based in Minnesota, announced this week that it has successfully produced squalene using its Calyxt-engineered Plant Cell Matrix™ biomass.

Squalene is traditionally sourced from shark liver oil, but companies across several industries, including cosmeceuticals and pharmaceuticals, have already begun to seek out alternative sources for use in their products. As a background, squalene is a high-end, oil-free moisturizing ingredient used in a wide variety of cosmetics. The livers of an estimated 3,000 sharks are required to produce just 1 ton of squalene. Up to 6 million deep-sea sharks a year were thus killed to meet the global demand of between 1,000- 2,000 tons/year. Squalene is also used in the manufacture of vaccines.

Advances in the purification of squalene have also allowed perennial botanical sources like olives to become a viable commercial alternative to sharks. Refined olive oil is now the primary botanical source of squalane. Olive oil, received from the first compression, holds about 400-450 mg per 100g of squalene, while refined oil contains about 25% less. In some cases, premium-quality olive oil contains concentrations of up to 700 mg per 100g.

Amyris produces farnesene and by-products, such as squalene, from engineered microbes. The company recently started its new precision fermentation plant in Barra, Bonita, Brazil, which will produce, among others, natural vanillin, sugar-based Reb M, squalene, hemisqualene and patchouli. The site has five self-contained lines for diverse molecule production and can concurrently produce all 13 of its ingredients. The facility is located adjacent to the Raizen sugar mill. The company’s Aprinnova joint venture with Nikkol Group, manufactures and markets the Neossance™ Squalane and hemisqualane products derived from the hydrogenation of squalene oil in North Carolina.

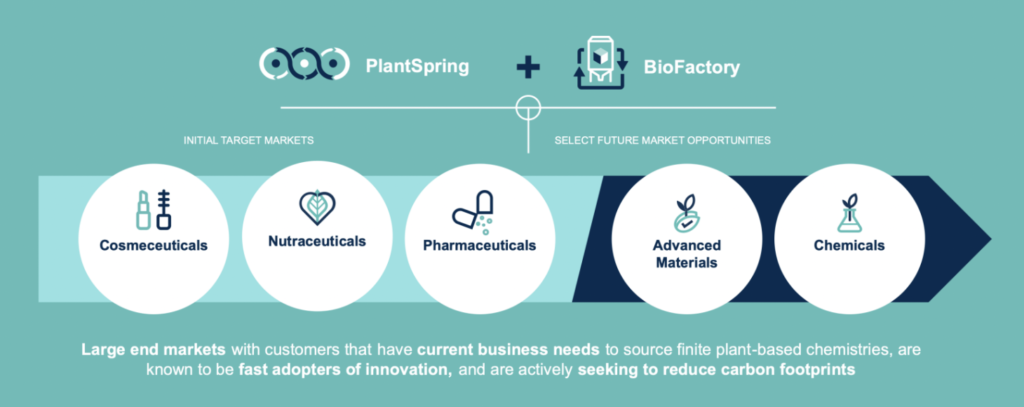

As for Calyxt, the company says it is working with its infrastructure partner, Evologic Technologies, to optimise speed to achieve commercial-scale production of its plant-based squalene. The company’s pilot bioreactor, the BioFactory™, at its Roseville, Minnesota, headquarters is already operational and can reportedly deliver new compounds ready for commercial scale production in less than 36 months. To be honest, I am not that familiar with Calyxt, although I do cover the company once in a while in Tecnon OrbiChem’s Bio-Materials news section. I remembered Calyxt’s development of high-oleic soybeans in my past coverage. I guess the company is now focusing more on nutraceutical, cosmeceutical, pharma, advanced materials and chemical industries leveraging its PlantSpring™ Technology platform and BioFactory™ production systems.

The BioFactory™ systems reportedly harness the potential of plant cells in a multicellular matrixed structure and utilise nutrient media for its production. PlantSpring™ is founded on Calyxt’s experience engineering plant metabolism and includes its scientific knowledge, its proprietary systems, tools, and technologies, and an expanding set of AIML (artificial intelligence and machine learning) capabilities.

I am not sure what is the current global market volume for squalene, but in 2020, Amyris was able to produce around 2,000 tons of the sugar-based molecule.

FOLLOW ME ON THESE SPACE

Discussion

Comments are closed.