Production of renewable diesel (processed via hydrocracking of fats and oils) continues to expand here in the USA as well as in Europe where large traditional oil and energy companies such as Neste, Valero, Total, Eni and now Phillips 66 are now becoming or have become major players. For those who are subscribers of Tecnon OrbiChem’s Biomaterials newsletter, don’t forget to revisit your May 2018 issue where the Chemical Profile is about bio-naphtha (a co-product of renewable diesel production).

In the meantime, let me share this news early this month about Phillips 66 and Renewable Energy Group (REG) planning to construct a large-scale renewable diesel plant in Washington State which will use REG’s BioSynfining technology. Planned feedstocks include a mix of waste fats, oils and greases including regionally-sourced vegetable oils, animal fats and used cooking oil.

The new facility will be constructed adjacent to the Phillips 66 Ferndale Refinery in Washington State. The Ferndale Refinery already has an existing infrastructure that included tank storage, a dock and rail and truck rack access. The companies expect to make a final investment decision in 2019. If approved, production at the new facility is expected to start in 2021.

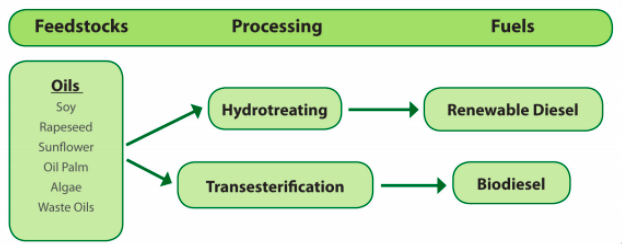

A presentation from the recently-held ICIS Pan American Oleochemicals conference that I attended in late October in Miami, Vantage Oleochemicals’ Deborah Baldwin noted that renewable diesel in Europe is already replacing 3.7m tons of the traditional biodiesel (which is transesterified fats and oils) production in the region. More renewable diesel projects are also expected to start in Europe with investments from Total and Eni. Estimated renewable diesel production in EU for 2018 is forecasted at 2.48 billion liters coming from 14 biorefineries.