Our friend from Sustainability Consult sent this news release about their client, the US-based start-up DMC Biotechnologies. The company recently announced its partnership with two major French industrial leaders, Danone and Michelin, and with Crédit Agricole Centre France, a key investor in the region, to create a EUR16 million Biotech Open Platform project to bolster the development of advanced fermentation processes, particularly precision fermentation, on a larger scale. The industrial and technological platform will be located in Clermont-Ferrand within the Parc Cataroux Center for Sustainable Materials, an innovation accelerator supported by Michelin. The Biotech Open Platform is also supported by several public and private institutions: the University of Clermont Auvergne, the company Greentech, the Auvergne-Rhône-Alpes Region under the European Regional Development Fund (ERDF) and Clermont Auvergne Métropole.

So what is Precision Fermentation?

According to DMC Bio, precision fermentation is a cutting-edge technology that uses microorganisms such as bacteria, yeast, or fungi to produce proteins, enzymes, and other molecules used in industry. It is particularly suited to innovation in the agri-food and materials sectors. The primary distinction between precision fermentation and fermentation is that the microorganisms used are designed to create a particular end product. Precision fermentation is a more advanced kind of metabolic fermentation, where living organisms convert organic chemicals from the feedstock into usable components. For example, precision fermentation is used in the food and pharmaceutical industries to produce biopharmaceuticals.

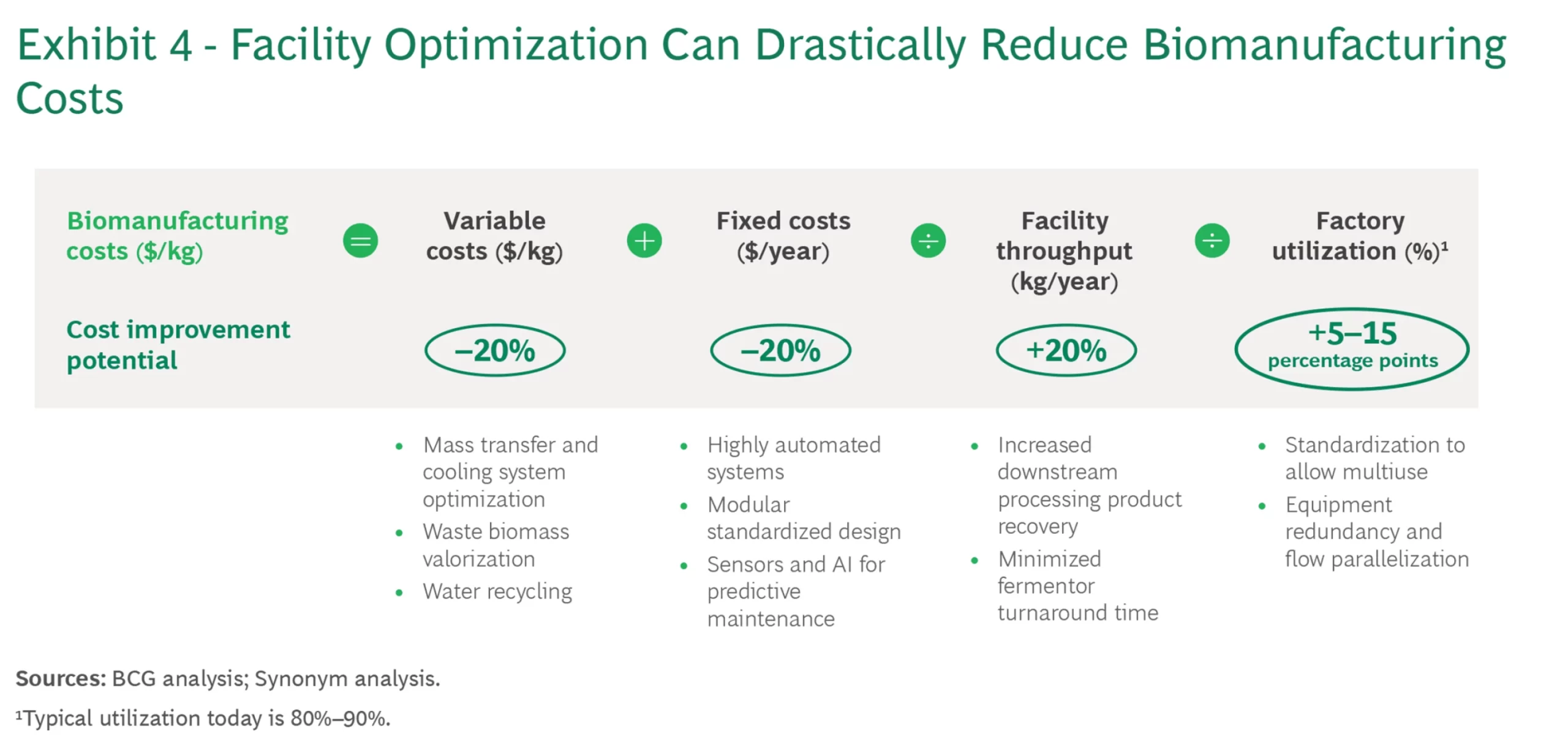

Precision fermentation remains an underused technology despite continuing advances in genome engineering and strain development because of the high cost of production, which stems from adherence to rigorous standards to ensure high quality. Biopharmaceuticals are typically served by contract manufacturing organizations (CMOs), which typically provide a capacity of less than 100,000 liters. Non-pharma biomanufacturers must invest significant upfront capital for downstream processing, making the economics more unfavorable for the precision fermentation of industrial products.

The Boston Consulting Group released a report on the state of biomanufacturing prepared in collaboration with Synonym—a developer of physical, digital, and financial biomanufacturing infrastructure. The report details how biomanufacturing can finally fulfill its promise of achieving commercial scale. Some of the necessary innovations, such as AI and high-precision sensors, will require technological advances, but many involve only cost optimization related to process engineering. These levers focus on high-cost items such as energy demand and labor and maintenance, which companies can apply today. The report estimated that scaling up industrial precision fermentation can create a $200 billion market by 2040, seven times the current size if companies build enough production capacity to lower costs.

“The development of the new Biotech Open Platform will enable us to accelerate the scale-up and commercialization of new products leveraging our transformative fermentation technology.”

Kenny Erdoes, CEO of DMC

The press release stated that the Biotech Open Platform will accelerate the development of precision fermentation by enabling the scale-up of innovative products and processes already tested in the laboratory. By 2025, the project plans to install an initial demo-scale production line, including a fermenter and purification equipment. Additional equipment, including a second production line, will be installed in the following years. This ramp-up will enable the platform to meet the scale-up needs of its founders and to gradually open it up to other companies facing the challenge of scaling up in the industrial biomanufacturing sector.