It’s Saturday and I am still working on my Biomaterials newsletter (poor me!) but I just want to post this press release from the US DOE as I find this technology very interesting. Cut and paste story below:

The National Renewable Energy Laboratory (NREL), together with leading petroleum refining technologies supplier W.R. Grace, and leading pilot plant designer Zeton Inc., built a unique pilot-scale facility that can produce biomass-derived fuel intermediates with existing petroleum refinery infrastructure. This pilot plant, constructed in part with funding from the Bioenergy Technologies Office, combines biomass pyrolysis together with fluid catalytic cracking—one of the most important conversion processes used in petroleum refineries—to demonstrate the potential to co-process biomass-derived streams with petroleum, at an industrially-relevant pilot scale.

There are 110 domestic fluid catalytic cracking units currently operating in the United States. Using them to co-produce biofuel could enable production of more than 8 billion gallons of bio-derived fuels, without construction of separate biorefineries. This would significantly contribute to the Renewable Fuel Standard mandate set by the Energy Independence and Security Act of 2007 to produce 21 billion gallons of advanced renewable transportation fuels by 2022.

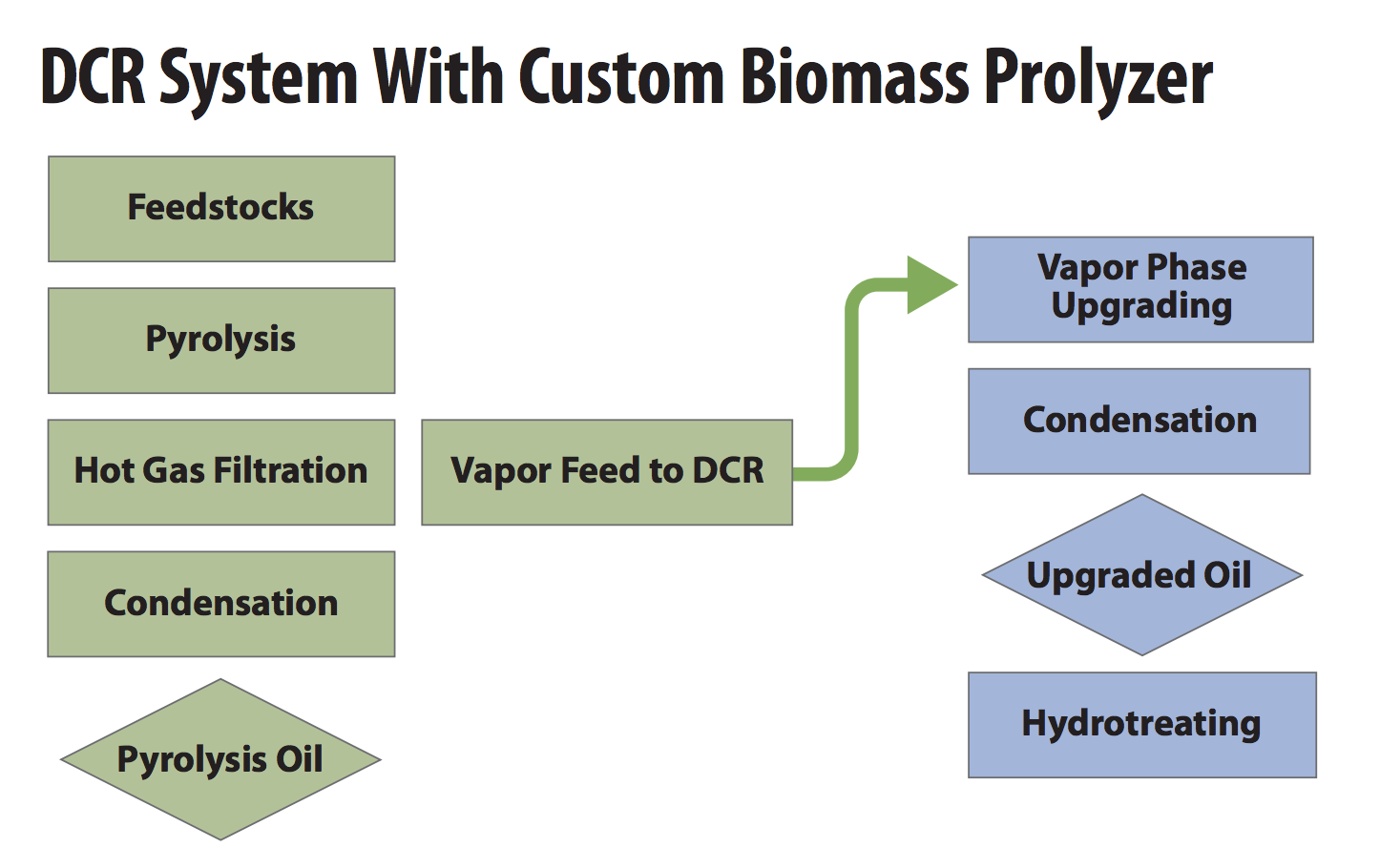

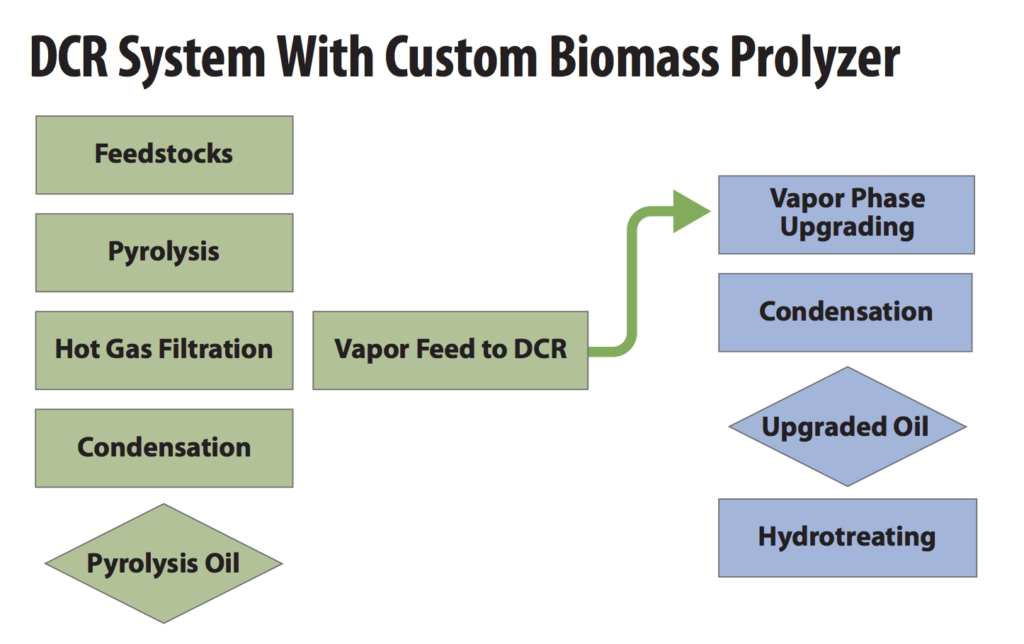

The front end of this innovative pilot-scale system makes use of fast pyrolysis—the rapid heating of biomass to 400–600 °C in the absence of oxygen followed by cooling the resulting vapors into a liquid bio-oil—an efficient method for converting all fractions of biomass (about 70% of the total mass and energy) into a liquid product. However, upgrading this liquid product poses unique challenges, as bio-oil is acidic, chemically unstable, and contains more oxygenated compounds than petroleum crude oils. An effective approach to stabilize pyrolysis oil and minimize downstream processing challenges is to catalytically reduce the oxygen content before condensation of the vapors occurs.

This step takes place in a separate reactor unit called the Davison Circulating Riser Reactor (DCR), designed by W.R. Grace. NREL’s custom biomass pyrolyzer produces vapors which are then fed to the DCR, where they undergo fluid catalytic cracking to yield a highly deoxygenated oil consisting mainly of hydrocarbons. This product can then be further finished into a conventional fuel blendstock at a petroleum refinery, where existing infrastructure can be leveraged to reduce the overall cost of upgrading. Earlier this year, co-processing verification experiments with biomass-derived vapor and petroleum demonstrated that biomass components were integrated into the liquid gasoline product.

Housed within the Vapor Phase Upgrading Laboratory at NREL, the coupled pyrolyzer-DCR pilot plant enables a wide range of experimental conditions for continued catalyst evaluation to improve the quality and yield of the bio-oil intermediate. The data generated on both vapor and fuel product composition from these tests can be used to help inform efforts to enable refinery integration. This equipment will also be available to companies who would benefit from the opportunity to test their materials and processes without the time and expense of building their own pilot plant facility.

Housed within the Vapor Phase Upgrading Laboratory at NREL, the coupled pyrolyzer-DCR pilot plant enables a wide range of experimental conditions for continued catalyst evaluation to improve the quality and yield of the bio-oil intermediate. The data generated on both vapor and fuel product composition from these tests can be used to help inform efforts to enable refinery integration. This equipment will also be available to companies who would benefit from the opportunity to test their materials and processes without the time and expense of building their own pilot plant facility.

NREL’s bioenergy research, funded by BETO, is the largest national laboratory bioenergy program across the eleven Energy Department national laboratories that conduct bioenergy research. BETO’s Conversion Research and Development Program aims to drive down the cost of biofuel and bioproducts from non-food sources to a level cost competitive with petroleum-based fuels and products.