Unfortunately, I’m having a not-so Chrismassy holiday break in the hospital being poked and prodded the past week so all I can do for now is blog a bit with some cutting and pasting on my mobile app.

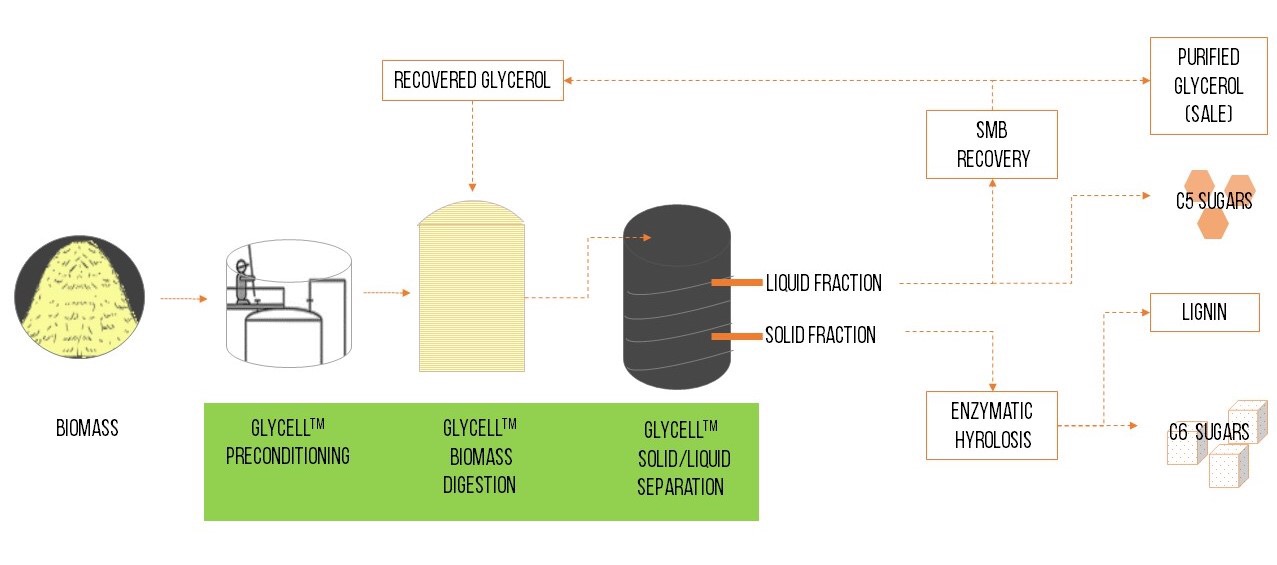

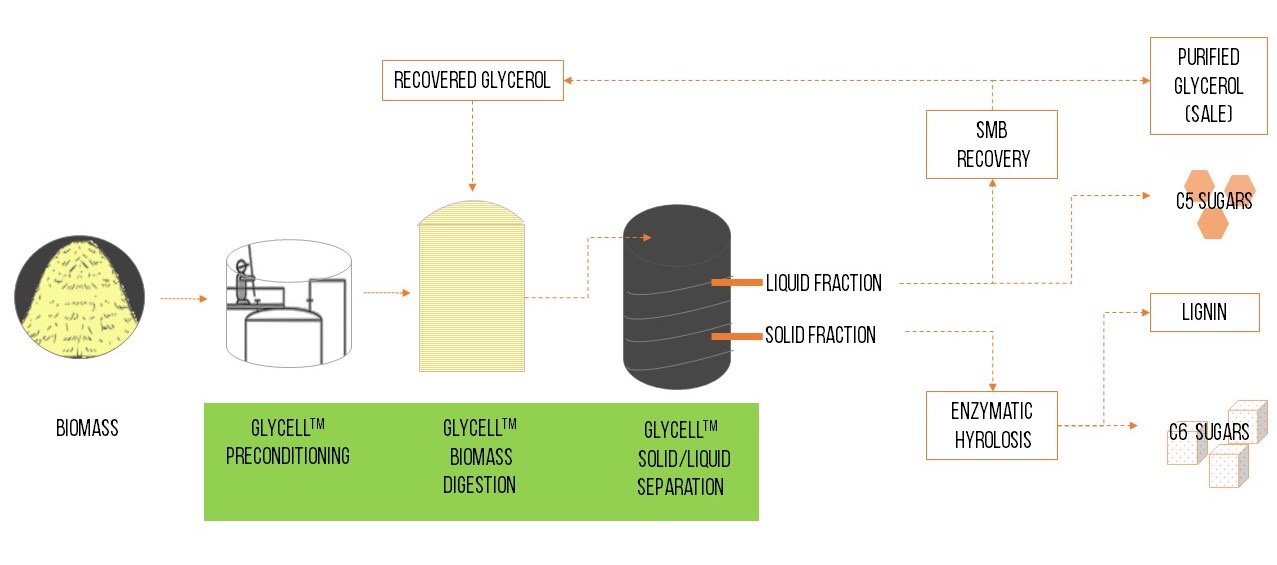

Here’s a recent one from Our Australian friends Leaf Resources. The company has developed a patented biomass pretreatment process called GLYCELL, which uses glycerine to economically produce cellulosic sugars.

Leaf Resources recently announced a collaboration with Novozymes, the world’s largest producer of industrial enzymes, to further increase the yields and efficiency associated with Leaf Resources’ innovative biomass conversion technology.

The GLYCELL technology operates at low temperature and pressure, and uses crude glycerin as a low cost, recyclable reagent. The process efficiently deconstructs plant biomass and produces a high-yield of high-quality, concentrated cellulose and hemicellulose sugars, which in turn enables cost competitive production of renewable chemicals.

As part of the collaboration, Novozymes will customize its broad portfolio of robust, high-yielding enzymes to the GLYCELL process. The goal of the collaboration is to design a highly tailored enzyme package that allows the GLYCELL process to achieve superior performance, quality, and reliability for the production of high-value renewable chemicals. Leaf and its development partner, Claeris, LLC, will then incorporate Novozymes’ tailored enzyme package into the biomass pretreatment section of integrated biorefineries.

Leaf Resources strives to become a key player in the conversion of biomass to functional sugars, thereby accelerating the expansion of the fast-growing renewable chemicals market.

I have covered some of Leaf Resources’ recent activities and also interviewed the company for Tecnon OrbiChem’s Biomaterials newsletter.