Miss me? I miss blogging too, and for those who recently contacted me via email, my apologies for the delayed response. A lot of personal things going on but I am trying to get back into the green groove.

We have several green chemical news that came out this week but let us start first with LanzaTech’s carbon dioxide-based acetic acid partnership with Malaysian oil and gas company Petronas, which is also a current investor in the company via its venture arm Petronas Technology Ventures Sdn Bhd.

The companies will work together to develop and commercialize acetic acid production using waste carbon dioxide (sourced from refinery off gases and natural gas wells) as feedstock.

“Rather than trying to sequester carbon deep into the earth, we will “bury” it in a chemical. In this way, companies can not only comply with emissions reduction requirements, but also generate revenue along the way.” – Jennifer Holmgren, LanzaTech CEO.

This is the first time that LanzaTech has announced development of CO2-based acetic acid. According to the company, acetic acid is a $4.5bn global market (9m tons/year) that can be saturated quickly. Holmgren said they have started looking at converting acetic acid/acetate to lipids, and that some research have indicated that this is possible.

“Lipids are a great way to get to jet, diesel and gasoline, as well as other products like food and cosmetics.”

This is the first time that the blog has ever heard of such conversion so this will be an interesting development to follow…

In the meantime, I also asked LanzaTech if the Petronas collaboration will use the bacteria Clostridium magnum as I came across several references on LanzaTech’s usage of this microorganism in producing acetic acid. Holmgren said LanzaTech will not be using the C.magnum bacteria but another one of their own proprietary unmodified organisms. (UPDATE: The blog originally stated that the microorganism was from Petronas but this is incorrect)

Last question was about the timeline for the project and the company said the collaboration is still at the beginning stage and therefore no firm projection is still decided at the moment.

For more on LanzaTech, you can check out my ICIS article on my interview with Holmgren in June.

Given the blogger’s curiosity on this CO2-to-acetic acid process, I came across several research references that dated back to 1930s. One example is the carboxylation of methane using a solid catalyst.

I also remember during my field trips back then at ICIS that Wacker Chemie has been developing its own biobased acetic acid and has investigated three routes namely:

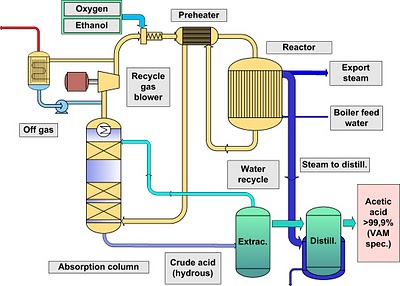

- ACEO Process – involves a biomass feedstock being converted to ethanol (using yeast) and producing acetic acid via gas phase oxidation process. Wacker’s ACEO process was said to be able to produce more than 90% bio-acetic acid yield.

- Fermentation to Butanediol – Ferments biomass feedstock using bacteria to butane 2,3 diol, which could be then dehydrated to produce methyl ethyl ketone (MEK) or directly produce acetic acid via gas phase oxidation. Acetic acid from MEK is also possible via gas phase oxidation.

- Homoacetate Fermentation – Ferments biomass feedstock to acetate/acetic acid using bacteria.

Commercial-scale acetic acid today is mostly produced via methanol carbonylation process using synthesis gas from natural gas and coal (this one mostly from China).

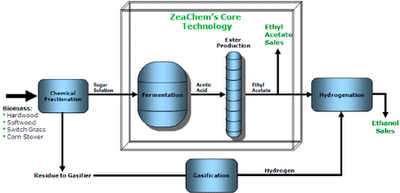

Another company involved in developing biobased acetic acid is Zeachem.

The blog’s last interview with Zeachem was in January this year when the company started its 250,000 gal/year biorefinery in Boardman, Oregon. The demonstration biorefinery — currently producing acetic acid and ethyl acetate using locally-grown hybrid poplar — will be used for testing purposes.

Zeachem plans to have a commercial 25m gal/year plant — they are hoping to start construction in 2013 — as soon as the demo plant has proven its design and metrics. According to the company, the biorefinery will be flexible enough to produce 100% cellulosic ethanol if needed or varying volumes of ethanol, ethyl acetate or acetic acid, whichever product is in demand.

Zeachem’s demo biorefinery will use about 2,500 bone dry tonne of feedstock (100 gal ethanol per bone dry tonne). For the 25m gal/year commercial plant, the company expects to produce about 110 gal/bone dry tonne of feedstock and ultimately increasing to 135 gal/bone dry tonne.

The biorefinery will also have the ability to make ethylene, olefins and jet fuel.

As for CO2, there has been a lot of chemical companies looking at the use of this greenhouse gas for polymer feedstock. New York-based Novomer has been developing its CO2-based polypropylene carbonates (PPC) and polyethylene carbonates (PEC) that contain between 43% and 50% CO2 by weight.

The polymers are based on the co-polymerization of CO2 and propylene oxide or other epoxides. Novomer also has developed chain transfer technology to produce low molecular weight CO2-based polyols for thermoset applications.

Another company working on PPC under the trade name Green Pol is Korea-based SK Innovation. The company is planning to commercialize their Green Pol plastic around 2013-2014. Plant construction, commercial testing and market development for the bioplastic is already ongoing, according to the company.

Three-year old California-based Oakbio said it is able to capture CO2 from flue gas using a fermentation process and convert CO2 to bioplastics and chemicals. In July, the company said it was able to successfully produce yields of over 50% biopolymer in microbe biomass by dry weight from inputs of raw flue gas and electricity at Lehigh Southwest Cement Company’s Cupertino, California plant.

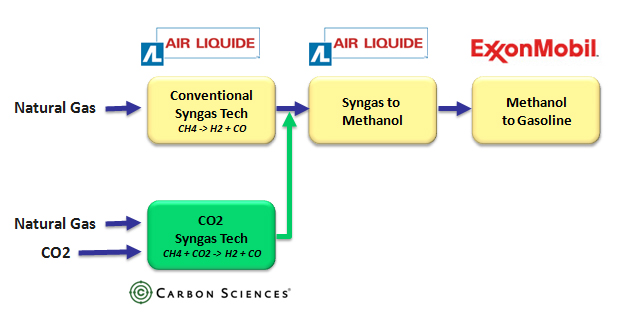

Another California company Carbon Sciences, is looking to utilize waste CO2 using its dry reforming catalyst technology to produce syngas as feedstock to make chemicals and fuel. The company is currently planning to produce gasoline from combined natural gas and CO2.

Chemical firms such as Evonik, BASF, and Bayer MaterialScience (BMS) are also active in the development of CO2-based polymers.

According to this July press release from the Nova Institute, Siemens and BASF already successfully demonstrated the first applications in household appliances – refrigerator compartments and vacuum cleaner covers – at the ACHEMA fair in Frankfurt in June 2012.

The refrigerator components were made of PPC/PLA (polylactic acid) combinations; the vacuum cleaner covers were made from a compound of polyhdroxybutyrate (PHB) bioplastic and PPC containing 43% CO2 (by weight) supplied by BASF.

The properties of the latter composite are such that it can replace ABS (acrylonitrile-butadiene-styrene) in a host of applications. The addition of PPC to the PHB and PLA considerably reduced the brittleness of these biopolymers, eliminating the need for certain additives and enabling easy processing using normal machinery. Siemens is further on the look out to examine whether they can replace other types of plastic with CO2 based composite materials.

BMS was said to have showcased its “Dream Production” polyurethane samples at ACHEMA, which were made from CO2-based polyols. Since last year, BMS has been manufacturing test batches of CO2-based polyurethanes at a pilot plant in Lervekusen, Germany.

The CO2 used in this process is sourced from a power plant operated by RWE near Cologne. It is removed from the flue gas and liquefied for transportation.

BMS said if things go well, the company will start industrial production of foams for mattresses and insulation materials for refrigeration and construction purposes using the CO2-based polyol in 2015.

Evonik has been doing its research on using CO2 as feedstock for polymers and specialty chemicals in collaboration with three German universities—Aachen, Dortmund and Bochum—as part of the H2ECO2 project. This three-year project is funded by the Ministry for Innovation, Science, Research and Technology of the federal state of North Rhine-Westphalia and co-financed by the European Union.