I had several interviews last month and a few of them I will post in the blog as all the interviews I did was already published on Tecnon OrbiChem’s Bio-Materials newsletter.

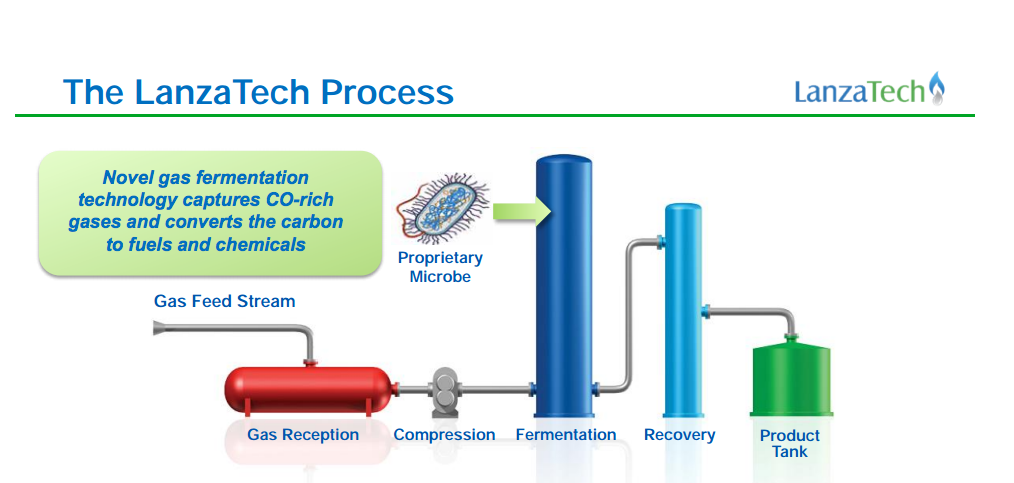

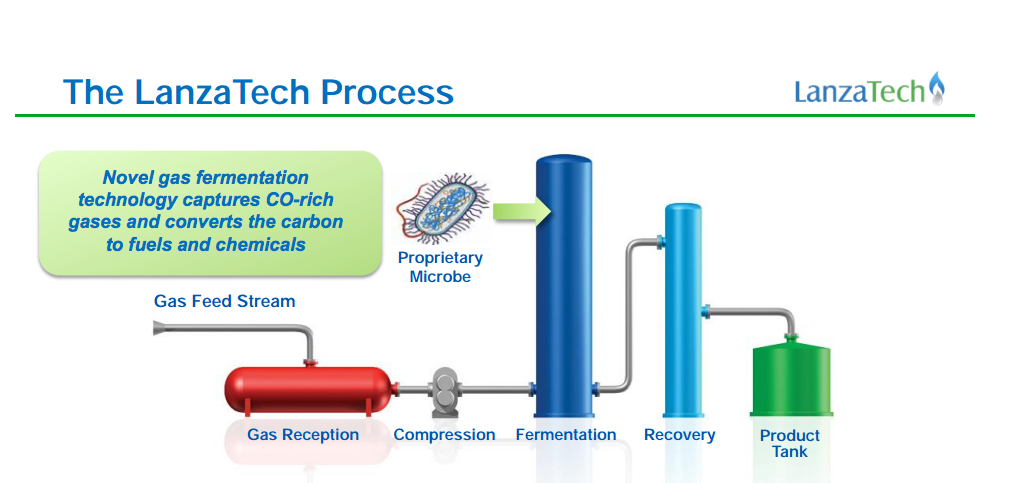

During the recent BIO World Congress in Philadelphia, INVISTA and LanzaTech announced that they have signed a research and development agreement on projects that will use LanzaTech’s gas-fermentation technologies to convert CO2/H2 feedstocks into a range of industrial chemicals in a one-step process using proprietary INVISTA host organisms and metabolic pathways.

If successful, the first commercialization of this technology is expected as early as 2018. The companies did not indicate what kind of chemicals will be produced but INVISTA noted that these chemicals will be a good fit for their current products portfolio. INVISTA will be the one that will determine what kind of chemicals they want to focus on given that it is INVISTA’s microorganisms that will be used in these projects. LanzaTech will focus on the gas fermentation processing.

INVISTA will work on its microorganisms at its own laboratories, while LanzaTech plans to work on the gas fermentation process using these microorganisms at its new pilot facility in Skokie, Illinois, US headquarter, as well as at its Freedom Pines facility in Soperton, Georgia. If successful, the first commercialization of this technology is expected as early as 2018, with INVISTA doing the manufacturing of these chemicals.

INVISTA is a well-known global manufacturer of nylon, spandex (under the Lycra brand) and other polymers and fibers. The company had several collaborations on the development of bio-based chemicals and materials, including its Lycra brand, which the blog recently posted.

In 2012, INVISTA started its collaboration with LanzaTech to develop bio-based butadiene as feedstock for INVISTA’s proprietary adiponitrile (ADN) production technology. ADN is an intermediate chemical used in the manufacture of nylon 6,6. The companies initially plan to convert carbon monoxide (CO) to 2,3 butanediol (2,3 BDO), and then subsequently convert it to 1,3 butadiene (BD) using gas fermentation. Longer term, the companies plan to produce CO-based BD directly using a single step process via gas fermentation.

Too bad I was not able to attend LanzaTech’s presentation at BIO World Congress about their bio-BD developments, but according to LanzaTech, the company has already produced 2,3 BDO at a pilot scale at its 15 kgpy New Zealand facility, which is located at a nearby steel mill where they can get plenty of waste CO. The company is also working with 2,3 BDO at its pilot facility in Freedom Pines.

In this project, LanzaTech owns the organism being used to produce the 2,3 BDO using the company’s gas fermentation process. LanzaTech has partnered with SK Innovation, which will focus on the thermocatalytic production of butadiene from 2,3 BDO. LanzaTech said it is on schedule for the bio-butadiene project and expects to be ready in 2015 in designing commercial units. No comment, however, on when the actual bio-butadiene commercial production will take place as it will be up to INVISTA to do so.

The companies are also looking to produce bio-butadiene in a one step-process without going through the 2,3 BDO route.

As for LanzaTech’s other bio-based chemicals projects:

- The company has partnered last year with Evonik on a 3-year research cooperation to genetically modify organisms that can produce specialty plastics using LanzaTech’s gas fermentation technology

- It has partnered with Global Bioenergies in 2011 to work on organisms that will produce isobutene from carbon monoxide

- It has partnered with Petronas and Indian Oil on acetate-to-lipid conversion by yeast or algae

- It is working on an ARPA-E project to convert methane into lipids using methanotrophs

LanzaTech said its pre-commercial facility in Shanghai with a capacity to produce 100 kgpy of ethanol using steel mill gases from Baosteel has already met and exceeded all production targets last year. Another 100 kgpy plant with its second Chinese partner, Shougang Group, is also in current operation in Beijing producing ethanol using steel mill gases. LanzaTech plans to have its first full commercial-scale production with around 30 mgpy capacity producing ethanol from steel mill gases to be completed by 2015.