In PLA news, BI-AX International, a packaging film and sheet specialist, has launched an entirely new line of its Evlon biaxially oriented sheet products developed in collaboration with NatureWorks. This new biobased sheet made from Ingeo biopolymer reportedly provides a competitive alternative to polyvinyl chloride (PVC ) and high-impact polystyrene (HIPS), credit, key and gift cards as well as signage and folded cartons made from those petroleum-based plastics. This extension to the Evlon line offers a heat stable sheet with exceptional stiffness – ideal performance factors for sheet stock used for cards, signs, and cartons.

With its first sheet product offered at 10 mils (254 microns), this entrant marks a significant product line expansion for BI-AX, as the company adds heavier gauge sheet products to what was already a comprehensive Evlon portfolio of 20-75 micron films.

According to NatureWorks, Ingeo biobased cards not only offer performance enhancements, but also deliver price stability compared to volatile, petro based materials. Evlon sheet stiffness allows thin-gauging and materials savings. The new bioplastic is available in 10 mil gauge in white and clear formats, offering exceptional stiffness, strength, heat stability and deadfold.

Evlon’s high gloss sheet possesses high surface energy, parameters which reportedly provides for outstanding printing. BI-AX co-extrusion capabilities mean the company is able to offer multilayer structures with an adjustable skin layer which facilitates customization of surface properties such as coefficient of friction, heat sealability, and tint. This co-extrusion capability has allowed Evlon film to seal at lower temperatures than most orientated polypropylene (OPP) films, making it ideally suited for flexible film packaging.

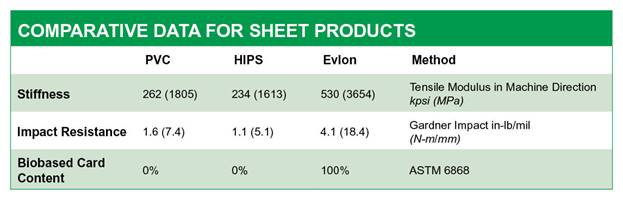

The table below shows how the new 10 mil Evlon biobased sheet offers much better stiffness and impact resistance compared to PVC and HIPS. These properties lead to great durability as well as the ability to reduce the gauge of the sheet while maintaining the performance of thicker gauge petroleum based materials.