I promised myself I won’t work and check any of my emails during my 2-week long holiday vacation (I don’t remember taking 2 successive weeks off for the past 4-5 years) but I always consider blogging as a personal hobby so I am making an exception when it comes to GCB posting.

Back in December 2007 during my first year of blogging, I remember posting my “Top 10 new green products launch”, and probably most of the products in that list are all based on greenwashed marketing but unfortunately, I can’t retrieve that post anymore. I had fun posting that list, however, so I’ve decided to try it again this year with more noteworthy product recommendations from companies that I’ve covered and reported about for years. It’s never too late to shop for great holiday gifts (for some of them that are already out in the market) so here’s my list in no particular order.

Zara Garments from Waste Carbon

Fashion retailer Inditex announced that its largest brand, Zara, has designed a capsule collection that incorporates fabric made with waste carbon emissions using carbon capture and fermentation-based chemical conversion technologies developed by Chicago, Illinois-based company, LanzaTech. The technology converts waste CO2 via fermentation into ethanol, which is a chemical building block used in the production of polyester materials such as PET.

Adidas Stan Smith Mylo™ Shoes

California-based biotech company Bolt Threads has partnered with adidas for the creation of the new Stan Smith shoes made with mycelium-derived leather called Mylo™ developed by Bolt Threads. Stan Smith is the first adidas shoe to feature Mylo™ material. It reportedly took 4,000 samples and about a year of working with Bolt Threads to ensure the sustainability, aesthetic and performance standards that could hold up to the process of making the sneaker. The material is being used in the tongue and toe box, quarter panels, heel patch and heel logo of the Stan Smith shoe. adidas is now working to refine the manufacturing process to consistently make hundreds and then thousands of the Stan Smith Mylo™, which is expected for a commercial rollout and increased scalability in 2022.

AirCarbon® Foodware and Fashion

California-based PHA technology developer Newlight Technologies own its two consumer brands, Restore Foodware straws and cutlery and Covalent Fashion that includes accessories such as sunglasses, handbags, wallets, computer sleeves, cardholders, and cellular phone sleeves, which are made from AirCarbon® biopolymer. The biopolymer is approximately 40% oxygen from the air and 60% carbon from greenhouse gas by weight. Newlight recreates ocean conditions at its facility using salt water, air, recaptured methane gas and powered by renewable energy. The ocean-degradable biopolymer called PHB is produced from the fermentation of methane feedstock using patented microorganisms found in the ocean. The PHB yield is reportedly high enough to allow them to produce at scale.

Stella McCartney’s faux fur by Sorona®

Stella McCartney’s faux fur by Sorona®

Stella McCartney was the first to debut last year a garment during the Paris Spring Fashion Week that incorporates a faux fur made with DuPont’s Sorona® PTT bio-based fiber. The faux fur is manufactured under the brand Koba® by Ecopel. Brands such as Maison Atia and Karl Lagerfeld are now featuring styles incorporating Sorona® faux fur. DuPont developed Sorona® polymer in the late 1990s using the bio-based monomer Bio-PDO™ as its basis. The biological process for creating Sorona® polymer reportedly utilizes 30-40% less energy and releases 56-63% fewer greenhouse gas emissions than nylon 6 and nylon 6,6. Sorona® for faux fur is made with 70% to 100% bio-based Sorona® polymer fibers and can be mechanically recycled.

Biossance Skincare Products

California-based Amyris through its 50/50 JV Apprinova has been producing its Biossance™ skincare line since 2015 which is based on fermentation-based squalene and hemisqualene. The Biossance™ brand was created as an alternative to the prevalent use of squalene derived from sharks as an emollient in cosmetic products. Sugarcane-based squalene can lower costs by 80% and can be made available in unlimited quantities when needed. In December 2016, Amyris sold a 50% stake of its Neossance® farnesane-based squalane business to Japan-based cosmetic specialty chemical provider, NIKKOL Group. By the way, you can probably get a good discount for Biossance™ products this holiday season.

Global Bioenergies’ color cosmetics that LAST

France-based Global Bioenergies launched in 2021 its proprietary long-lasting makeup and lip brand called LAST®, which will reportedly combine long-wear, absence of transfer, water-resistance and naturalness for eye makeup and lip care. This performance is essentially based on using renewable isododecane produced by Global Bioenergies as the main ingredient in the formulas. The LAST® brand is currently made up of mascaras, eyebrow mascaras, eye shadow, and lip care, all of which have a hold of at least 24 hours. Production for the cosmetic products has started in the Lyon factory of MS-Beautilab, reportedly one of the largest cosmetic manufacturers in Europe. The company is selling its cosmetic products with the same price range as conventional best-seller brands with the same product positioning but using bio-based isododecane as the sole differentiating factor.

Sugarcane-based LEGO® plants

In 2018, LEGO® started using sugarcane-based PE which is said to be perfect for making smaller, softer pieces such as trees, branches, leaves and accessories for mini-figures that are included in manyLEGO® sets. Bio-PE is not currently suitable for making harder, stronger elements such as the iconic LEGO® bricks. The company even introduced its own new character called Plantus Maximus for its LEGO® plants which has a mission to protect the planet.

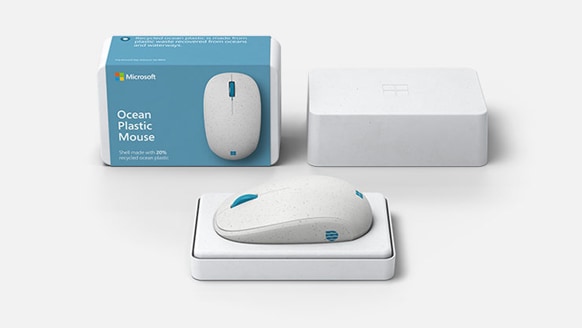

Microsoft’s Ocean Plastic Mouse

It has been a long time since I last used a computer mouse but if you still do, Microsoft has been collaborating with SABIC in the use of its new XENOY™ resin comprised of 20% ocean plastic incorporated in the exterior shell of Microsoft’s new Ocean Plastic Mouse. Microsoft began this project with the objective of creating a plastic resin made from at least 10% recycled ocean plastic as part of its commitment to achieving zero waste by 2030. For every 1,000 tons of product containing recycled ocean plastic XENOY™ PC/PET compound, an equivalent of 24 million single-use 0.5litre PET water bottles is reportedly removed from the ocean, ocean-feeding waterways or ocean-adjacent shores. Microsoft Ocean Plastic Mouse is available in select markets for $24.99.

WNDr® Alpine Algae-based Ski

For ski enthusiasts, California-based materials innovation company Checkerspot Inc. has launched last year its Vital 100 ski through its outdoor direct-to-consumer brand WNDr® Alpine. Vital 100 features Checkerspot’s new Algal Cast and Algal Hard Foam polyurethane materials designed to optimise backcountry ski performance and to eliminate the use of petro-based ABS plastic sidewalls from the ski’s construction. WNDr® came to market with an Algal Core, a high-density composite derived from microalgae polyol. The company is currently developing its algal PU in several different applications such as a sample tail block made out of 100% algal PU that the company is hoping to introduce in 2022.

Frito Lay’s Off The Eaten Path

And last but not the least, need some stocking stuffers? Snack manufacturer Frito-Lay, a division of PepsiCo® launched last month an industrially compostable bag for its Off The Eaten Path® brand snack packaging, which are now available at Whole Foods Market and select US retailers. The packaging is primarily made from non-food, plant-based sources. Frito-Lay also has a collaboration with TerraCycle where consumers can sign up on the TerraCycle program to either mail in the packaging to be composted or locate a local composting drop-off location through TerraCycle’s database. As an added incentive, the brand will donate $1 and up to $192,000 to Ocean Conservancy for every specially- marked industrially compostable bag returned to TerraCycle by 30th May 2022.

There are many, many more examples of renewable-based products already out in the market and most of those I report at Tecnon OrbiChem’s Bio-Materials monthly report. January 2022 will be our 101 issue and I will write my yearly market update on several bio-based chemical building blocks and polymers. Enjoy the holidays, stay safe and healthy, and looking forward to hopefully, a pandemic-free 2022.