The use of waste-based feedstock is an important milestone for the renewable chemicals industry as it will further emphasize the industry’s sustainability and hopefully will lessen the cost of production in the long run (although market economics dictate that nothing is free if there is demand for it).

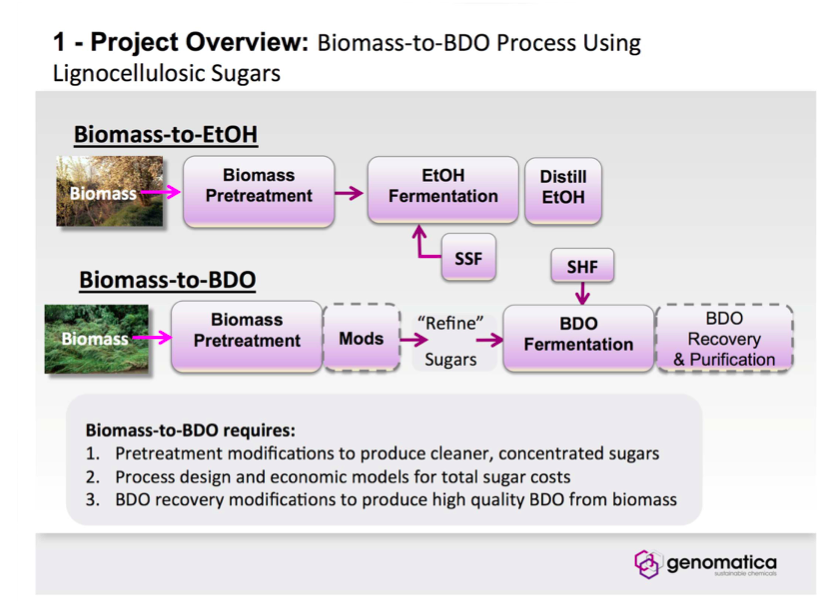

Genomatica recently announced that it made significant progress in the use of biomass feedstock that can advance the prospects for the economical production of polymer-grade chemicals such as 1,4 butanediol (BDO). Through advances in strain engineering and process design, the company has developed a sugar specification for biomass pre-treatment technologies to produce sugars compatible with its GENO™ processes.

Genomatica said it has assessed ten technologies against that standards and it has demonstrated at least four among those ten technologies that can currently produce sugar suitable for the commercial production of BDO from a quality standpoint. Under a $5 million US DOE-funded project, Genomatica has demonstrated the level of commercial readiness for the production of BDO from lignocellulosic biomass using engineered E.coli.

For an integrated process from biomass to BDO, an improved production strain enabled Genomatica to achieve BDO production titer exceeding 120 grams/liter at a rate of 3.1 grams/liter/hour, which is reportedly well-above the proposed titer target of 70 grams/liter at a rate of 2.5 grams/liter/hour. However, the yield result was still lower than the proposed value.

Genomatica believes that its sugar specification and vendor evaluation is the industry’s most extensive effort at characterizing and enhancing the suitability of pre-treatment technologies for non-fuel applications. Genomatica said its sugar specifications will eliminate the guesswork, and gives vendors targets that are more precise than that required for fuel or ethanol applications.