This is another interview that is a bit late in posting. I have been covering several new technologies since late last year for Tecnon OrbiChem’s Bio-Materials newsletter, where these new technologies are now using feedstock such as methane, syngas and carbon dioxide/carbon monoxide to produce various chemical intermediates.

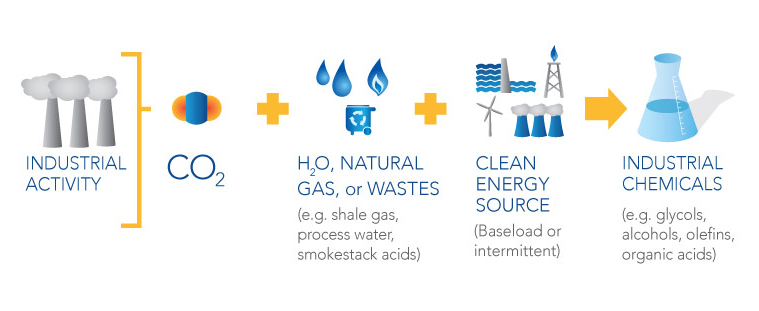

Are these bio-based feedstock? They could be if these greenhouse gas emissions come from biomass. However, most of the interest in North America are now on waste gas or stranded gas from natural gas fracking. Of course, there are also interests in capturing these waste gas from industrial manufacturing facilities.

This New Jersey-based start-up company, Liquid Light, recently unveiled its new process for the production of monoethylene glycol (MEG) from carbon dioxide (CO2), utilizing its low-energy catalytic electrochemistry technology, combined with hydrogenation and purification processes.

Some of the waste gas-to-chemicals technology uses fermentation such as what LanzaTech and Calysta Energy have been doing, or traditional chemocatalytic processing such as what Novomer has been working on.

Liquid Light uses another traditional chemical process – electrochemistry – using proprietary catalysts. I always think of chlorine production when I think of electrochemistry, and this is exactly how it works although in this case, the type of products manufactured depend on the type of co-feedstock and catalysts used, according to Liquid Light CEO Kyle Teamey. The company said its process can scale up in a predictable manner akin to world-scale chlor-alkali plants.

The beauty of electrochemistry is that it can use electricity from solar, wind and renewable energy source, thereby further lowering its’ products’ carbon footprint.

Aside from MEG, Liquid Light can also produce a wide range of C1-C4 chemicals simultaneously in a one step process by adjusting the design of its catalyst and using co-feedstocks along with CO2. On CO2-to-MEG production, about 1.5 units of CO2 is required to produce 1 unit of MEG.

Preliminary projections, based on Liquid Light’s laboratory-scale production analysis, indicated that the company’s technology will require a CO2 cost of $125/ton or less to make a ton of MEG. The current cost of industrial CO2 using conventional carbon capture technology is estimated at around $80/ton, although it can range widely between $5 and $150 per ton depending on sources. The company uses relatively pure, pipeline grade CO2 for its Meg production.

In terms of cost-economics, Liquid Light said its CO2-based MEG can compete with low-cost shale gas-based MEG. Other MEG production processes require an estimated $617 to $1113/ton of feedstocks derived from oil, natural gas or corn. MEG sells for about $700-$1400/ton depending on the feedstock used.

Liquid Light aims to license this technology and it is looking for partners especially in the chemical space where companies can take advantage of this value-added use for waste CO2 from their manufacturing facilities. Current estimates show that a 400 ktpa Liquid Light MEG plant would offer more than $250 million in added project value as compared to a plant built using the best currently available process technology. The company said a 625 ktpa plant would have a 15 year net present value of over $850 million to a licensee.

Liquid Light is currently proceeding to build its pilot reactor, and from there to a demonstration scale unit with a goal for commercialization of large-scale systems by around 2017-2018. The company’s processing unit is a modular design, where multiple reactor cell units can be stacked together enabling flexibility for licensees to make smaller amounts of specialty chemicals or to build a larger facility for high-volume commodities like MEG.

Liquid Light started in 2008 and currently has about 25 employees.

By the way, did I mention in passing that German specialty chemical company, Evonik, has also been developing a technology that uses CO2 to produce bicarbonates? Creavis, the strategic innovation unit of Evonik, has been developing this for several years under a publicly-funded project called H2ECO2, which was supported by the state of North Rhine-Westphalia and the European Union.

Production of bicarbonates is based on soybean oil, which is esterified in the presence of a biodiesel catalyst from Evonik. The epoxides are formed using hydrogen peroxide, also from Evonik, and then the final step is a carbonation reaction with CO2.

Bicarbonates can be used in applications such as plasticizers for PVC and also as oil additives.

Finally, I found this interesting video from Scientific American on the challenges of using waste CO2 as chemical/fuel feedstock.

One response to “Introducing: Liquid Light’s waste CO2-to-MEG tech”

I gone through your blog. it is really good. Nice to read. Hope it will help to all. Thanks for sharing this. see my blog also.

Please visit the website:

Carbon Dioxide Manufacturers