The greenblogger has been busy setting up meeting appointments for the incoming NPE plastics trade show to be held late this month. In April 9, I will be moderating a CEO Roundtable session at the Plant Based Summit that will be held in Lille, France (exciting!).

Speaking of France and polymers, let me introduce this France-based company, NaturePlast, which recently developed, through its subsidiary, Biopolynov, PLA resin grades with a high thermal resistance of above 100 degree Celsius as well as having improved mechanical properties, improved productivity compared to existing heat-resistant PLA grades, and most of all cost-competitive with standard PLA resins.

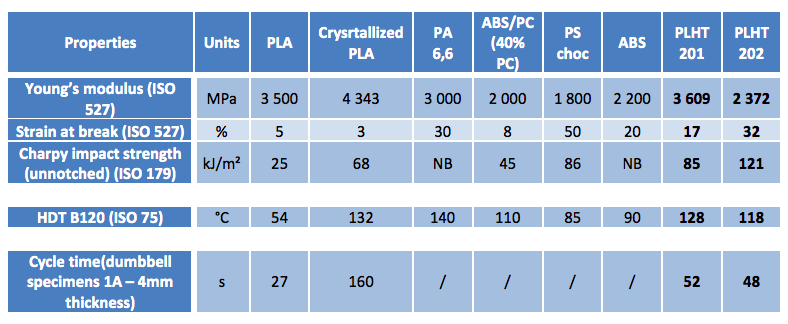

Heat-resistant PLA grades with thermal stability of up to 120 degree Celsius already exists on the market but in injection moulding applications, these heat-stable PLA products were reportedly expensive and the cycle time is significantly higher compared to a non-modified PLA. Natureplast trials reportedly allowed the company’s PLA to gain in cycle times from 30% up to more than 200% depending on injected parts.

The company is offering the new resin grades under the brand, PLHT 201 and PLHT 202. PLHT 202 can reportedly be compared to ABS (acrylonitrile butadiene styrene), and is even superior in terms of thermal and impact resistance. Applications for the new PLA grades are targeted at automotive and electronic consumer goods. The resins can also be used as substitute for polypropylene and high density polyethylene.

Natureplast does not produce PLA in commercial basis but distributes it along with other bioplastics such as PHA, bio-PE, bio-PET, etc., to converters and end-users worldwide. Biopolynov, which was created in 2010, is an R&D company dedicated to modify/improve bioplastic properties.

Here is a video from the company but unfortunately it’s in French.

One response to “Natureplast develops heat-resistant PLA resins”

😉