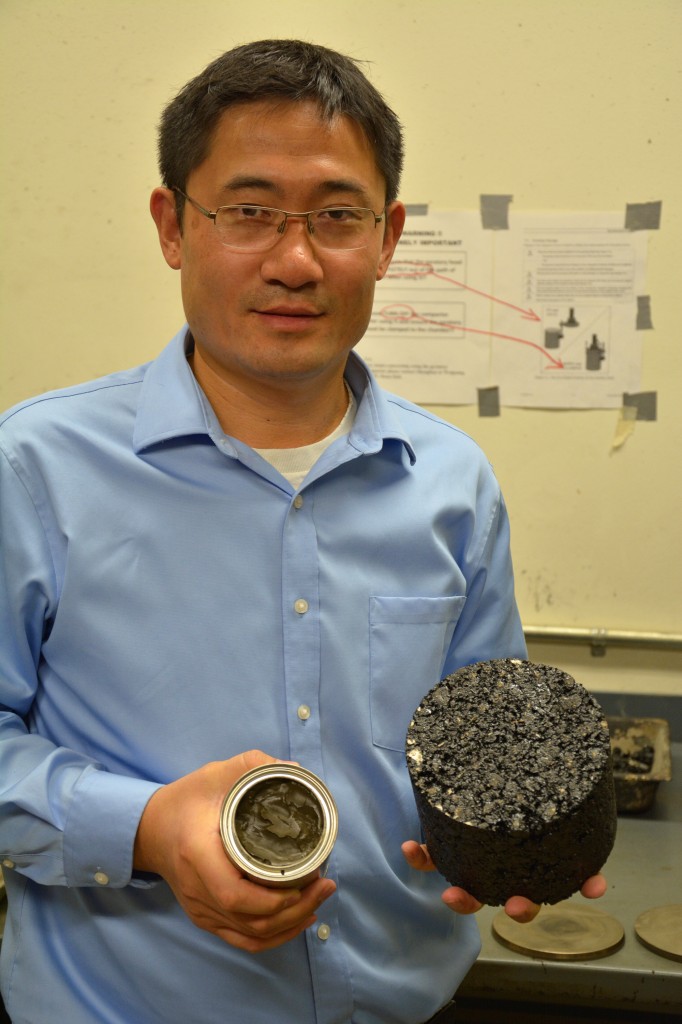

Haifang Wen, assistant professor of Civil Engineering in the Washington State University (WSU), Department of Civil and Environmental Engineering, has developed a technology to substitute restaurant cooking oil for the crude oil used traditionally in the production of asphalt, creating a sustainable bio-asphalt that looks and handles just like its petroleum-based counterpart.

Haifang Wen, assistant professor of Civil Engineering in the Washington State University (WSU), Department of Civil and Environmental Engineering, has developed a technology to substitute restaurant cooking oil for the crude oil used traditionally in the production of asphalt, creating a sustainable bio-asphalt that looks and handles just like its petroleum-based counterpart.

The researcher plans to construct a trial road—at least a quarter mile long, this summer. The bio-asphalt has already been subjected to a series of rigorous stress tests, such as intense heat, freezing temperatures, compression, and loading.

Wen recently received a 2014 Federal Highway Administration grant of $1 million to continue his research. It follows a $190,000 grant from the National Science Foundation.

Faced with increasing petroleum prices, new environmental regulations, and changes to the crude oil refining process, asphalt has become a scarce and costly commodity. Asphalt, made from the residue left behind after production of gasoline, plastics, and other materials, still commands $700-800 per ton, or half the price of gasoline at $1,500 per ton, Wen estimates.

The US is said to consume about 30 million tons of asphalt binder for roads every year, more if it includes roofing shingles. Asphalt binder, the sticky glue that holds crushed stone and sand together to form pavement, accounts for about 5% of the final hot mix asphalt (HMA) that is steamrolled into glossy new lanes and boulevards.

The WSU researcher estimates that it can reduce the cost of asphalt binder to under $200/ton using the waste cooking oil technology.

One response to “WSU develops waste cooking-oil based asphalt”

THe old saying that if it is too good to be true it probably is certainly comes int play here. Used cooking oil currently sells for $560 per ton down from the price last summer of $780+ per ton. So how can one produce $200 a ton binder from a raw material that costs more than that?