Over the years, the development of bio-based superabsorbent polymer (SAP) has been limited, and more so for biodegradable SAP. Very few companies have been able to reach past the pilot production phase for bio-based acrylic acid, the key intermediate used in the production of SAP. Cross‐linked polyacrylates are the most common type of SAP produced today. Acrylics dominate the SAP market owing to their relatively inexpensive raw materials and ease of synthesis from high-molecular-weight products. This prohibited market entry for drop-in bio-based acrylics that can be made from feedstock such as sugar, glycerine, and even CO2. Aside from polyacrylic acid, other raw materials used to produce SAP include polyacrylonitrile (PAN), polyvinyl alcohol (PVA), polysaccharides, and starch.

The majority of SAP produced worldwide (~90%) is used to manufacture personal hygiene products such as diapers, sanitary napkins, incontinence pads, and wound care dressings. The personal hygiene market is a $145 billion annual global industry. Because of the high stability, very high molecular weight, and low water solubility of polyacrylates, this results in the inability of microorganisms to degrade them and a tendency to cause environmental pollution problems. Researchers have begun to focus on various natural and biodegradable SAPs that achieve superabsorbent properties.

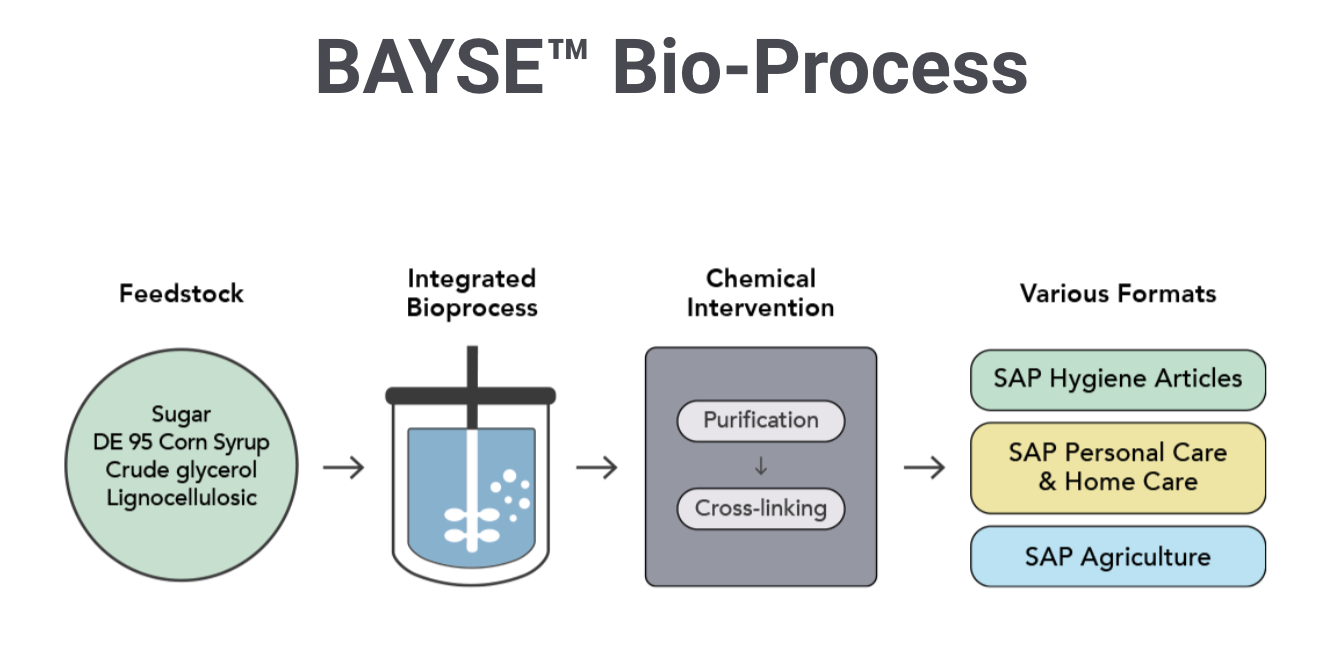

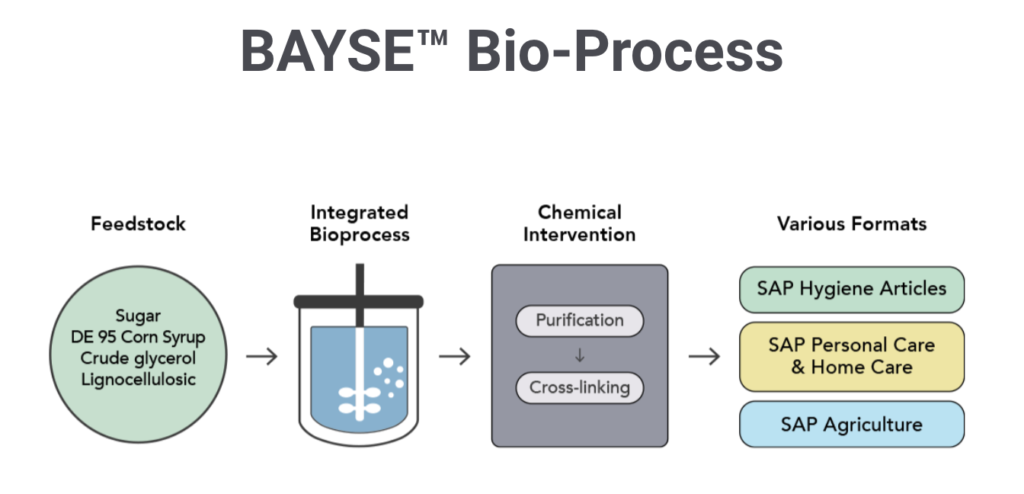

ZymoChem, a California, USA-based biotech start-up company, recently unveiled the world’s first 100% bio-based and biodegradable SAP under the tradename BAYSE™. ZymoChem raised $21 million in Series A funding in January this year to accelerate the commercialization of BAYSE™. The investment is led by Breakout Ventures with participation from new investors, including Lululemon Athletica, inc. and Toyota Ventures, and existing investors, including GS Futures, KdT Ventures, and Cavallo Ventures. In November 2023, ZymoChem received a $4 million grant from the US Department of Energy Bioenergy Technologies Office (BETO) to develop its microbial fermentation processes in the production of SAP.

ZymoChem’s proprietary technology platform reportedly allows for the production of BAYSE™ at a cost competitive with traditional SAPs. While BAYSE™ is a direct replacement for petroleum-derived polyacrylate SAPs, BAYSE™ is readily biodegradable and has a lower carbon footprint. According to ZymoChem, this addresses the significant environmental concerns posed by approximately 300,000 diapers per minute disposed of in landfills or incinerated. Not much information was shared about ZymoChem’s bio-based SAP. For synthetic SAPs such as polyacrylates to become degradable, inorganic additives are typically added to polyacrylic acid polymers to increase their solubility and improve degradation performance. Cross-linking acrylic acid with natural polymers has also been extensively studied to achieve both excellent absorbency and superior degradability.

Ecovia Renewables, a US-based biotechnology company spun off from the University of Michigan in 2014, has developed another type of bio-based and biodegradable SAP using polyglutamate polymers. The company’s AzuraGel™ Superabsorbent Biopolymers are produced through fermentation of 100% renewable biomass and reportedly show improved absorption over starch-based biopolymers. Ecovia Renewables has been very quiet since 2020. Back then, Ecovia was reportedly looking to partner in developing prototype diaper products and promoting AzuraGel™ for smaller applications to demonstrate its potential.

Låkril Technologies is another US start-up company developing a chemocatalytic process to produce acrylic acid using corn-based calcium and ammonium lactate feedstock. The company’s technology was spun off from the University of Minnesota in 2021. Calcium and ammonium lactate in dilute aqueous streams are typically available at low cost in lactic acid biorefineries. Låkril has licensed a patent-pending bifunctional catalyst technology from the University of Minnesota that can convert lactic acid to acrylic acid via thermochemical technology that can achieve greater than 90% yield and deliver greater than 35% CO2 reduction compared to petroleum-derived acrylic acid. The company is working on the development of an integrated process that will include pre-treatment and separation units.

Låkril Technologies secured over $1.4 million in total pre-seed funding in late 2022, led by the Iowa Corn Growers Association with participation from the Kentucky Corn Growers Association, as well as grants from the Minnesota Corn Research and Promotion Council, Indiana Corn Marketing Council, Corn Marketing Council of Michigan, and the National Corn Growers Association. The funding is expected to be applied to a planned pilot-scale operation. Låkril is currently producing on a bench-scale operation at the University of Minnesota.

Green D Market Analytics can provide a special report highlighting the market for renewable acrylic acid and associated derivatives, including superabsorbent polymers (SAPs). We provide our clients with confidential reports on the current renewable chemicals and biopolymers market landscape, including new and planned projects. Please contact us for more information about our customized client services, detailed market data, and special reports.