Technip Energies, a French engineering and technology company for the energy industry and chemicals sector, announced on 27 June its acquisition of Shell Catalysts & Technologies’ (SC&T) glycol purification technology to accelerate Technip’s commercialization of its Bio-2-GlycolsTM technology. This technology transfer agreement will combine Shell’s special catalysts to produce monoethylene glycol (MEG) from glucose with Technip Energies’ ethanol-to-MEG processes. The combined technologies will enable Technip to offer a more efficient, bio-based MEG production and commercialize it under the Bio-2-GlycolsTM trademark.

The conventional route for manufacturing MEG first involves oxidizing ethylene to ethylene oxide (EO) and then hydrolyzing EO to MEG. One of the issues in using ethanol feedstock in ethylene production is the high amount of sulfur in ethylene feed. Technip Energies press release about this acquisition did not share much information about SC&T’s catalyst technology. However, based on our research, SC&T can provide customized EO catalysts to work with the higher sulfur feed, allowing the customer to produce high-quality EO and MEG from renewable feeds. SC&T’s latest High Selectivity EO catalyst can achieve 92% selectivity, resulting in direct variable cost savings as less ethylene is consumed to manufacture MEG.

SC&T has been supplying India Glycols with its customized EO catalyst for over 20 years. India Glycols is currently the only global commercial producer of ethanol-based EO and MEG, with a production site located in Kashipur. India Glycols uses the ethanol-to-ethylene processing technology developed by US-based Scientific Design, a company of SABIC.

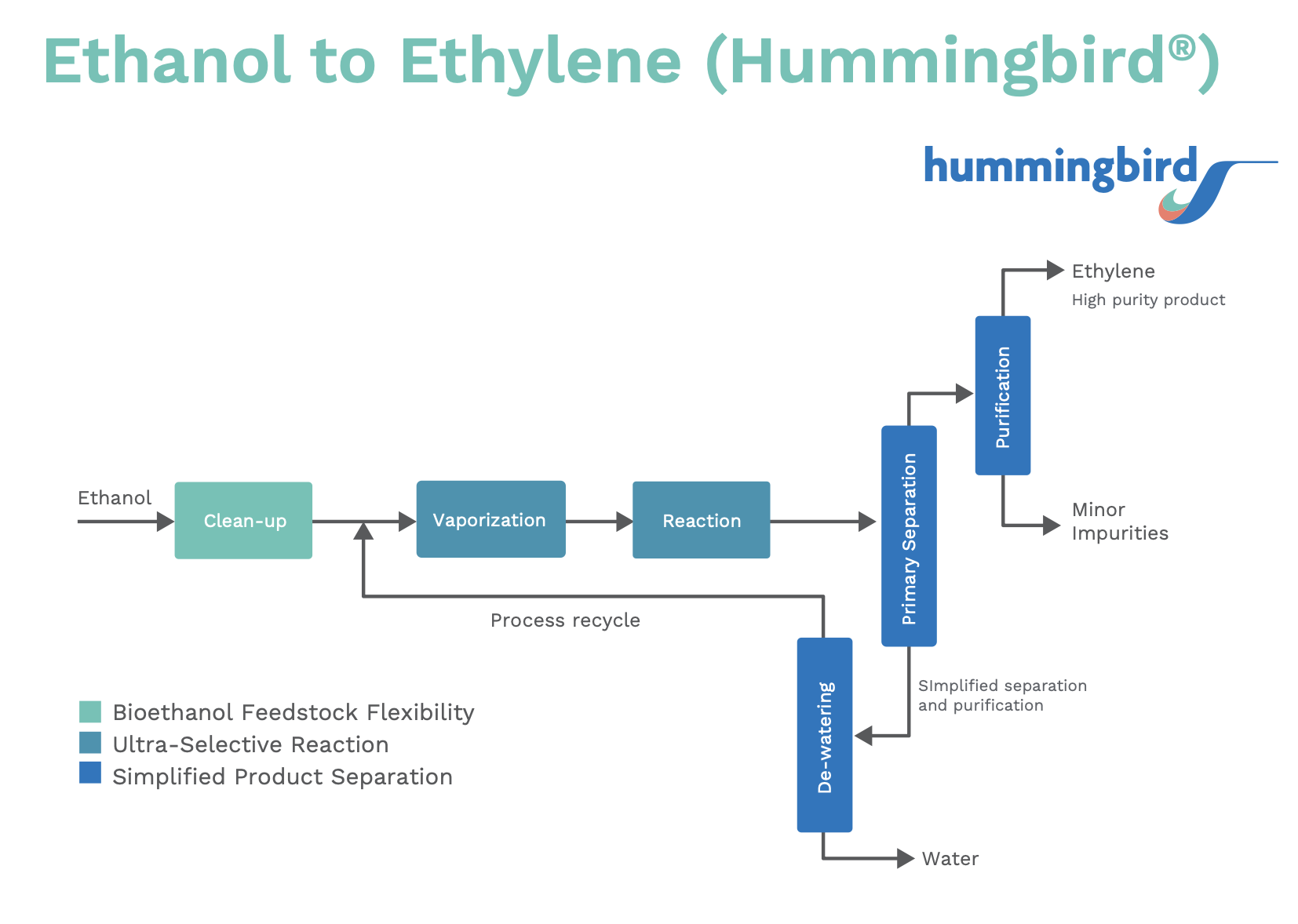

Technip Energies, on the other hand, has been building its renewable glycols portfolio for almost a decade. In 2016, Technip acquired the Hummingbird® ethanol to ethylene technology from BP Chemicals Ltd. This technology converts ethanol to ethylene through dehydration using a proprietary catalyst that can operate with mild operating conditions. The process uses a range of ethanol feedstocks and can easily be integrated into existing ethylene facilities.

In 2022, Technip Energies acquired the patents, technology, and rights for the process technology to produce corn ethanol-derived MEG developed by the Iowa Corn Promotion Board (ICPB). Since then, Technip Energies operated a pilot plant to commercialize the technology and make it available for licensing.

In 2023, Technip Energies signed a Joint Collaboration Agreement with LanzaTech that will combine LanzaTech’s carbon capture and utilization technology with Technip Energies’ Hummingbird® technology to transform waste carbon into ethylene. For this process, up to 95% of the CO2 in the flue gas is captured from the furnaces of an ethylene cracker and mixed with hydrogen. LanzaTech’s biorecycling technology will transform the captured waste carbon into ethanol, and finally, Technip Energies’ Hummingbird® technology will dehydrate the ethanol to ethylene. Technip Energies also partnered with LanzaJet, an independent company formed and spun off by LanzaTech. The collaboration with LanzaJet will produce sustainable aviation fuel (SAF) from ethanol using the Hummingbird® technology and the LanzaJet™ Alcohol-to-Jet process.

Green D Market Analytics can provide a special report highlighting the market for renewable ethylene and its associated derivatives, such as EO, MEG, and Polyethylene. We provide our clients with confidential reports on the current renewable chemicals market landscape, including new and planned projects. Please contact us for more information about our customized client services, detailed market data, and special reports.