Novamont announced yesterday the launch of their first product under the 4th generation Mater-Bi® line of biodegradable and compostable bioplastics. Unlike the first three generations, the 4th one has monomer components that will use biomass.

Novamont said there will be two innovative technologies will enable the company to produce key monomers from renewable resources: A) vegetable oil transformed into azelaic acid and other diacids through a chemical process; B) sugar-based 1,4 butanediol (BDO) via Genomatica’s technology.

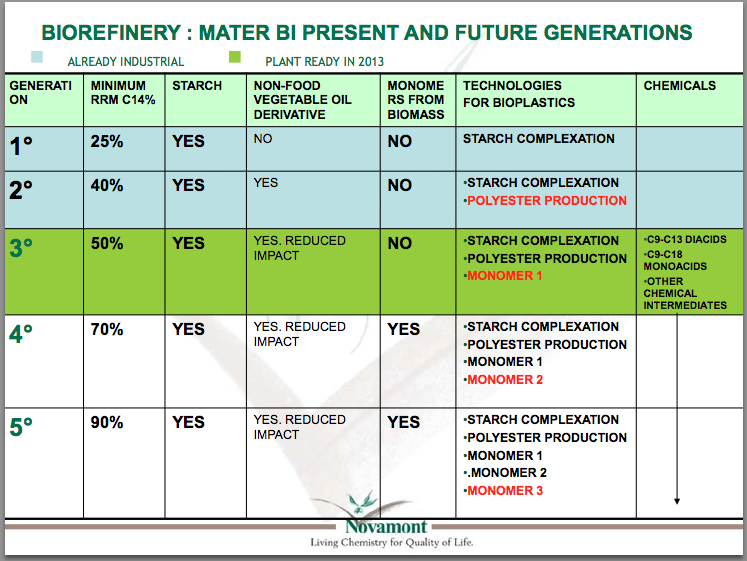

Here’s a slide (dated September 2012) presenting Novamont’s plans for its Mater-Bi® line of biodegradable and compostable bioplastics.

Earlier generation of Mater-Bi® are composed of starches derived from plants, mainly corn starch, and a fully biodegradable synthetic aliphatic-aromatic polyester called PBAT (polybutylene adipate co-terephthalate) trademarked under the name Origo-Bi. This biodegradable synthetic polyester technology made with combination of diacids (e.g. adipic acid and terephthalic acid) and diols (e.g. BDO), was acquired from Eastman, which was originally called Eastar-Bio, in 2004.

The blog is guessing that for the 4th generation Mater-Bi® line, instead of using petroleum-based monomers, adipic acid and BDO, adipic acid will be then be substituted by vegetable oil-based azelaic acid (the blog heard that this diacid is produced from rancidity of oleic acid) and Genomatica’s biobased BDO. Substitution of the aromatic terephthalic acid with a biobased material will still take time.

In preparation for this product, Novamont has been investing around €300m ($400.8m) with two new biorefineries via partnerships.

- A 50-50 joint venture with Eni Versalis called Matrica that will produce azelaic acid from vegetable oils in addition to other types of biobased chemicals and monomers at the JV’s Porto Torres, Italy, site. Novamont and Versalis are still

- A majority equity in a JV called MaterBiotech with Genomatica. The JV is expected to start operation of a 20,000 tpy bio-BDO plant later this year in Adria, Italy, at a former amino acid facility at Bottrighe owned by Ajinomoto subsidiary BioItalia.

Novamont currently has a 70,000 tpy capacity to produce Origo-Bi, as well as 120,000 tpy capacity to produce its Mater-Bi starch technology polymers in Terni, Italy.

3 responses to “Novamont launches 4th Gen bioplastic”

I haven’t seen much from the company about the Origo-Bi polyesters. Are they all used captively in the production of Mater-Bi blends?

It was difficult to get any current information on Origo-Bi. I think most are used in their production of Mater-Bi resins.

Sounds very good and innovative. Excited on how it will go on.