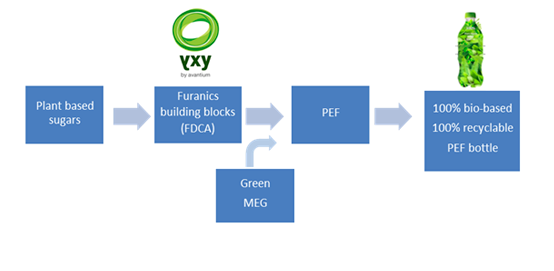

BASF and Avantium announced today their intention to establish a joint venture for the production and marketing of furandicarboxylic acid (FDCA), as well as marketing of polyethylenefuranoate (PEF), which is being touted as an alternative to PET but with better gas barrier properties and higher mechanical strength. For those who are not familiar with PET, it is a combination of monoethylene glycol (or in some cases diethylene glycol) and purified terephthalic acid. In the case of PEF, PTA is being replaced with FDCA and then combined with ethylene glycol.

While the companies are still in an exclusive negotiation phase (and anything can happen during negotiations), the plan is to build a reference facility for FDCA production at BASF’s site in Antwerp, Belgium, with an annual capacity of up to 50 ktpa. The JV will use Avantium’s YXY process for FDCA production. The aim is to build up world-leading positions in FDCA and PEF, and subsequently license the technology for industrial scale applications.

Avantium has been developing its YXY process in its laboratories in Amsterdam and pilot plant in Geleen, Netherlands for the production of FDCA. We recently posted on our Subscriber Area the current ongoing activities within the FDCA (or FDME in the case of DuPont/ADM partnership) market.

My Q&A with BASF/Avantium and analysis of this planned commercial development will be posted under the Subscriber Area and on Tecnon OrbiChem’s March Bio-Materials newsletter. The potential usefulness of FDCA as a building block like PTA (and not just for polyester use) is certainly becoming more of a reality.