I still have several interviews from last month that I need to post and I’m also receiving recent press releases so please bear with me as I try to juggle work and blogging. Next week, I will be at the ACSGCI Green Chemistry & Engineering conference in Bethesda, Maryland. Follow my tweets at @Dgreenblogger #gcande #greenchemistry.

In the meantime, let me post this news from Avantium announcing its recent €36 million ($50 million) financing round from a consortium of strategic players that consists of Swire Pacific, The Coca-Cola Company, DANONE, ALPLA, and existing shareholders.

Proceeds will be used to complete the industrial validation of PEF (polyethylene furanoate) and finalize the engineering & design of the company’s first commercial scale plant. As part of its strategy to use responsibly sourced plant based materials for PEF production, Avantium will validate the use of 2nd generation feedstock.

Avantium’s PEF resin, which is being offered as a 100% bio-based alternative to PET (polyethylene terephthalate), is made from the company’s patented YXY molecule based on 2,5 furandicarboxylic (FDCA) combined with plant-based monoethylene glycol (MEG). Avantium noted that PEF has properties superior to PET such as higher barrier to oxygen, carbon dioxide and water, extending product shelf life and reducing production costs. PEF is said to have carbon footprint that is 50-70% lower compared to today’s PET.

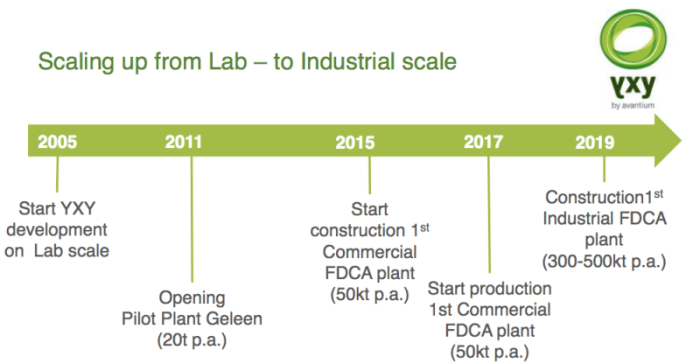

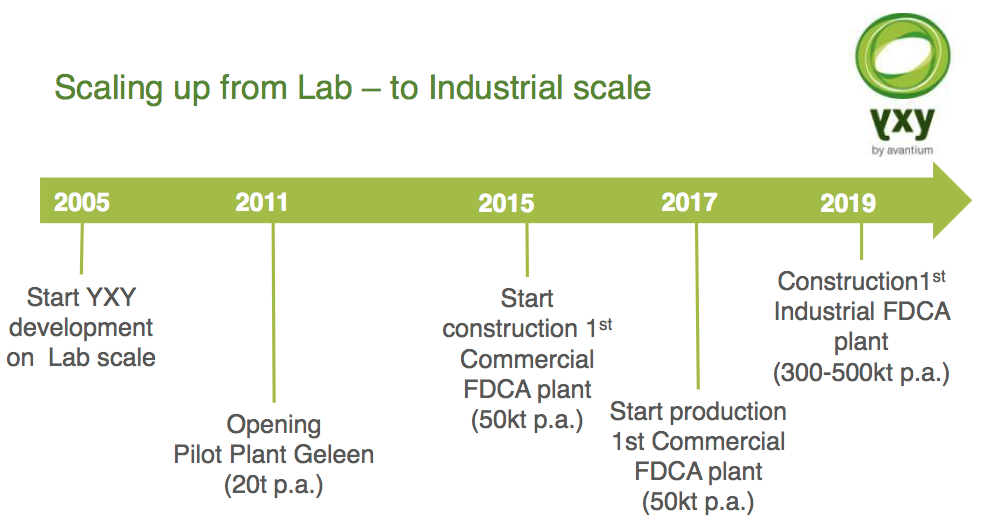

Avantium is currently producing FDCA from its 40 tonnes/year pilot plant in Geleen, the Netherlands. Avantium plans to start commercial production of FDCA and PEF in 2017 through a 50,000 tons/year plant although the company did not indicate where it will be located.

Avantium has partnered with Danone’s research organization to jointly develop recyclable PEF bottles for Danone’s global bottled water business. In late 2011, Avantium has also partnered with Coca-Cola. Last year, Avantium has partnered with European plastic converter ALPLA for the development of PEF bottles, as well as with Wifag-Polytype for the development of thermoformed PEF containers, drinking cups and trays.

According to Swire Pacific, Avantium’s technology represents a pathway to the next generation of bio-based packaging materials, and has huge potential application for Swire Pacific’s existing bottling businesses. The company, which is listed in the Hong Kong stock exchange, has diversified businesses including its beverage division under Swire Beverages, which is one of the largest Coca-Cola bottlers worldwide. Swire Beverages has the franchise to manufacture, market and distribute products the Coca-Cola Company in Hong Kong, Taiwan, seven provinces in mainland China and several areas of 11 states in the Western USA.

Swire Pacific noted that it is particularly interested in technologies concerning second-generation feedstocks especially using waste stream resources more effectively.

Coca-Cola said the improved barrier properties of PEF is important as it translates into a longer shelf life and more packaging choices for consumers. The improvement in the mechanical properties also translates to potential lighter weight bottles with reduced material usage and a reduced carbon footprint.

Danone also reiterated its search for a 100% renewable-based bottle that does not compete with food, and be 100% recyclable, which the company believes PEF can offer aside from having a good performance in terms of mechanical, thermal and barrier properties. Danone noted that a commercial plant for PEF is necessary in order to produce serious quantities that can be tested and tried out on the market.

ALPLA said it has been working with PEF with only a few kilos, and they treated it like gold. The company also would want Avantium to build up production so it can get more material, do more testing, and gain more experience in order to meet customer expectations, both in terms of performance and sustainability.