Avantium recently announced a signed agreement with Mitsui & Co. where Mitsui has been granted a right to purchase a sizeable volume of FDCA (2,5 furandicarboxylic acid) from Avantium’s planned commercial facility. Capacity, location and time lines are going to be announced in Q1 2016.

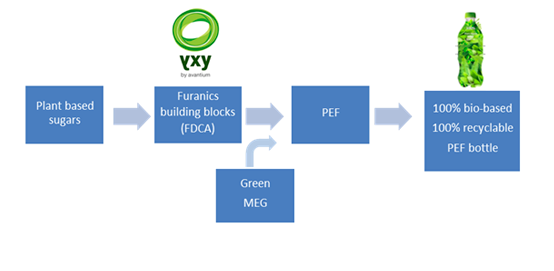

Avantium is said to be in the preparation stage of the construction of its first FDCA production plant. Avantium and Mitsui have entered into a development and roll out agreement for PEF (polyethylene furanoate) thin films in Asia and PEF bottles in Japan. PEF, which is being developed as an alternative to PET, is made from FDCA and monoethylene glycol. A 100% bio-based PEF means Mitsui will use bio-based MEG, which is already in commercial production.

PEF is being touted as having significant benefits over PET such as higher barrier to oxygen and CO2, which is suitable for packaging application for oxygen sensitive goods such as food, beer, and health care products. Other benefits include higher mechanical strength and a reduction in carbon footprint of more than 50% over PET.

Avantium and Mitsui are also looking to launch and grow the market for other FDCA-based applications such as co-polyesters. Avantium has already demonstrated the recyclability of PEF bottles into PEF fibers. The companies are hoping to launch PEF and other FDCA-based applications to the market well in time for the Tokyo Olympics (which will be in 2020 – I would love to go to Tokyo Olympics along with sportscaster brother!)

According to Avantium, PEF can be produced using conventional industrial PET production plants. More information about this deal on Tecnon OrbiChem’s December Bio-Materials newsletter.