Mitsubishi Chemical Corporation (MCC) recently announced that it is expanding production of its isosorbide-based engineering plastic, DURABIO, at its Kurosaki Plant in Fukuoka, Japan.

MCC has been producing its high-performance, high-transparency bio-based engineering plastic since August 2012 with annual production capacity of 5,000 tons. The company is planning to increase annual production capacity to 16,000 tons/year by fiscal year 2015.

MCC said it has developed a new grade of the DURABIO bioplastic that features excellent optical properties and high-resistance to heat and humidity. The company is aggressively promoting sales of DURABIO for use in touch panels on automobiles that control air conditioning, audio, and car navigation systems. The bioplastic reportedly also offers excellent flexibility in design and can enhance appearance of automobile interiors.

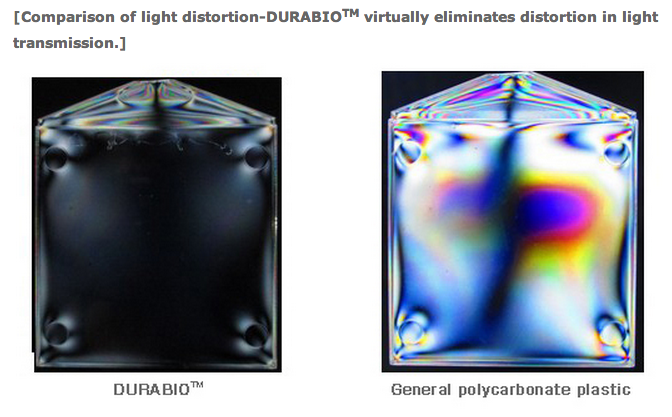

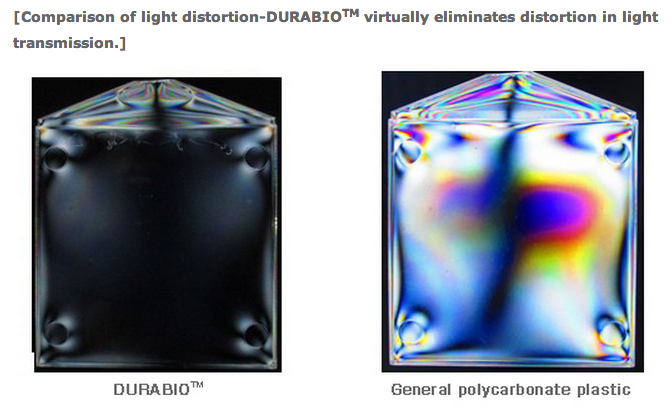

DURABIO is being marketed as alternative to impact-resistant petro-based polycarbonate. The disadvantage of traditional polyarbonates, according to MCC, is that it distorts in light transmission, which makes it difficult for uses to see the touch panel. The new grade nearly eliminated distortion in light transmission, making it easy to see the touch panel surface.

MCC anticipates much wider use and steady growth in demand for the isosorbide-based engineering plastic. Aside from automotive interior parts, MCC is also looking to use DURABIO in cell phones, film laminated steel sheet, lighting sheet, noise barrier wall, cosmetic containers, electrical and electronics housings, and as substitute for glass in front panel displays (such as TVs), sunglass, LED lighting and optical film.

Isosorbide producer Roquette is MCC’s feedstock partner. The isosorbide monomer is produced from sorbitol.

In another unrelated news, MCC has recently established a technology to mass-produce carbon black from plant oil with high efficiency. Carbon black is currently produced from coal- and petroleum-derived heavy oils, which are high in aromatic compounds such as creosote oil and ethylene residual oil.

MCC said it has been able draw upon its high-performance carbon black manufacturing technology. Rubber and plastic compounds made with the plant oil-based carbon black reportedly feature excellent processability.

MCC started test production at its Kurosaki plant in December 2010, and started supplying plant oil-based carbon black to its first customer in July 2013. The company is reportedly planning to expand production system while assessing market growth,