I know there had been several press release that came out today but let me post some of my previous Q&A interviews first. This one is from AVA Biochem, manufacturer of 5-HMF (hydroxymethylfurfural). I’ve reported a market analysis of 5-HMF at Tecnon OrbiChem’s April Bio-Materials & Intermediates issue, which also included this Q&A from AVA Biochem.

The company recently started operations of its 20 tpa 5-HMF facility in Switzerland. I believe the company will be presenting and exhibiting at the incoming BIO World Congress in Philadelphia, so this will be your chance to meet them in person.

Q: What are the derivatives of 5-HMF that the company sees an increase in focus in terms of use and development of 5-HMF?

A: AVA Biochem was set up in December 2011. We are currently focused on commercially producing the renewable platform chemical 5-HMF and opening up new markets for the substance.

The challenge of using biomass as a feedstock for chemical compounds is its high oxygen content – in other words, too many functional groups with oxygen, namely hydroxyl-groups. 5-HMF is available from biomass (fructose) by water elimination, but only has two functional groups. This is the optimal case, because for producing polymers the monomers should react “at two ends”.

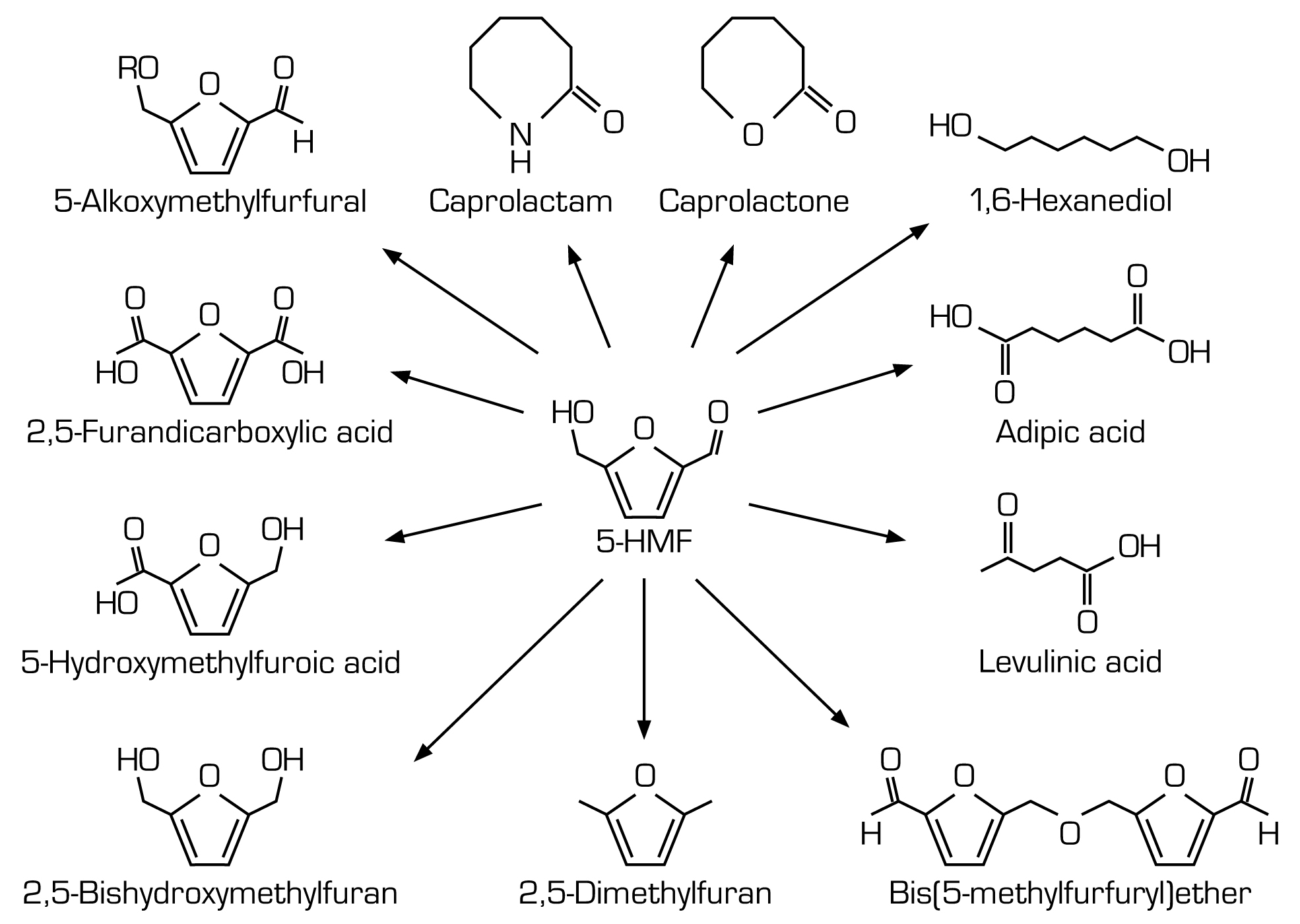

Through chemical modification of 5-HMF, different monomers are available. Monomers with two identical or two different function groups can be formed. This allows for a wide range of applications in producing biobased products, such as thermo-resistant resins, coatings, high-performance films, polymers or fibres. The polyethylene terephthalate (PET) market is another example of the numerous future opportunities of bio-based products.

Global PET output in 2009 was 49.2 million tonnes and PET fibre accounted for about two-thirds. PET for packaging and films accounted for 34%. Other opportunities include 2,5-Furan dicarboxylic acid (FDCA), one of the most important furan derivatives.

Thanks to its versatility, 5-HMF was identified by the US Department of Energy as one of the most valuable platform chemicals.

Q: What are the challenges in producing 5-HMF?

A: 5-HMF is produced by AVA Biochem using a modified hydrothermal carbonisation (HTC) process. This process was developed by our parent company, AVA-CO2, to turn wet biomass into CO2-neutral biocoal. AVA Biochem was set up by AVA-CO2, with additional investment from private investors, to commercialise 5-HMF. We are the first company producing renewable 5-HMF at commercial scale. Through process optimisation, we plan to increase production to 40 tonnes by the end of 2014.

One of the challenges was to develop high-purity 5-HMF reliably. Thanks to rigorous quality checks during the production process, AVA Biochem is now able to produce consistent purity levels of up to 99.9% in its Biochem-1 plant.

The main challenge is to develop a process which will allow the production of 5-HMF as a bulk chemical, opening up the long-awaited path to bio-based materials. While 5-HMF is already produced in smaller quantities, no one has been able to produce 5-HMF as a bulk chemical yet – even at a lower quality. Through its new and innovative process, based on a modified version of the HTC process, AVA Biochem has found a way to scale up the production process in order to produce bulk quantities of 5-HMF in the future.

Q: What is the current industry price range for 5-HMF?

A: We don’t comment publicly on price but we are selling commercially and encourage any potential customers to contact us directly to receive a tailor-made quote. 5-HMF is still considered to be a speciality chemical, mainly used in smaller quantities for research and development purposes. In the mid- to long-term, AVA Biochem will produce 5-HMF as a bulk chemical alongside industry partners, for large-scale applications in a range of industries e.g. chemical, plastic, pharmaceutical or food.

Q: What kind of sugars do you need to achieve 99% purity? Does the company need expensive catalyst to achieve this purity? What feedstock is the company currently using at the new pilot facility?

A: The AVA Biochem modified HTC process can transform biomass into sugars. Our plant in Muttenz, Switzerland is currently using fructose as a feedstock, but the technology is capable of creating 5-HMF from a range of different biomass.

The purity levels are not dependent on the feedstock itself, but rather on the process design and the rigorous quality controls implemented by AVA Biochem.

Q: Do you have a timeline for the scale-up production after 20 tons/year? What production volume do you intend to scale up next?

A: In this first phase, the plant is producing 20 tonnes/year of Swiss-made 5-HMF. The plant has the capacity to increase to 40 tonnes/year and we plan to scale up to this by the end of 2014.

AVA Biochem wants to support industry in its quest to replace petro-based chemicals and products with bio-based solutions. Together with potential partners, we are planning to build large-scale plants which will produce 5-HMF in bulk in the near future. Initial discussions with potential partners are ongoing and developing positively. With the biopolymers market alone expected to reach almost 1.5 million tonnes by 2018, 5-HMF’s global, long-term potential is vast.